The Power of Industrial Laser Equipment

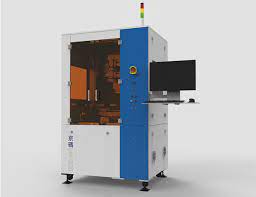

Industrial laser equipment has revolutionized the manufacturing and production processes across various industries. These high-powered tools utilize focused beams of light to cut, weld, engrave, and mark materials with unparalleled precision and speed.

One of the key advantages of industrial laser equipment is its versatility. From metal fabrication to automotive manufacturing, electronics production to medical device development, lasers are indispensable tools that offer unmatched efficiency and accuracy.

Lasers have the ability to work with a wide range of materials, including metals, plastics, ceramics, and composites. This flexibility allows manufacturers to streamline their production processes and achieve intricate designs that would be impossible with traditional tools.

Moreover, industrial laser equipment is known for its cost-effectiveness. By reducing material waste, minimizing downtime, and increasing productivity, businesses can achieve significant savings in the long run. The precision of laser technology also leads to higher quality finished products, enhancing overall customer satisfaction.

Another notable benefit of industrial laser equipment is its environmental friendliness. Unlike traditional machining methods that produce harmful waste and emissions, lasers operate cleanly and efficiently. This not only contributes to a safer working environment but also aligns with sustainable manufacturing practices.

In conclusion, industrial laser equipment represents a cutting-edge solution for modern manufacturing challenges. Its precision, versatility, cost-effectiveness, and eco-friendly nature make it an essential tool for businesses looking to stay ahead in today’s competitive market.

Key Insights on Industrial Laser Equipment: Leading Companies, Commonly Used Lasers, Investment Costs, and Startup Essentials

- What are the top industrial laser companies?

- Which laser is used in industry?

- How much does a good laser machine cost?

- What do you need to start laser business?

What are the top industrial laser companies?

When it comes to top industrial laser companies, several names stand out in the industry for their cutting-edge technology, innovative solutions, and reliable performance. Companies such as IPG Photonics, Coherent Inc., TRUMPF Group, and LaserStar Technologies are recognized for their high-quality industrial laser equipment that caters to a wide range of applications across various sectors. These industry leaders have established a strong reputation for delivering precision, efficiency, and durability in their laser systems, making them go-to choices for businesses seeking top-of-the-line solutions for their manufacturing and production needs.

Which laser is used in industry?

In the industrial sector, a variety of lasers are commonly used to meet specific application requirements. Some of the most prevalent types of lasers utilized in industry include fiber lasers, CO2 lasers, and Nd:YAG lasers. Fiber lasers are known for their high energy efficiency and precise cutting capabilities, making them ideal for metal processing applications. CO2 lasers are often favored for their versatility in cutting, engraving, and marking various materials such as wood, plastic, and textiles. Nd:YAG lasers are valued for their ability to deliver high power output and operate in harsh environments, making them suitable for welding and drilling tasks. The choice of laser type in industry depends on factors such as material properties, desired precision, speed requirements, and budget constraints.

How much does a good laser machine cost?

The cost of a good laser machine for industrial use can vary significantly depending on various factors such as the type of laser technology, power output, size, and additional features. Generally, prices for industrial laser equipment range from several thousand to hundreds of thousands of dollars. While it may seem like a significant investment upfront, it’s important to consider the long-term benefits and return on investment that a high-quality laser machine can provide in terms of increased efficiency, precision, and overall productivity. To determine the most suitable option for your specific needs and budget, it’s advisable to consult with industry experts and suppliers who can offer tailored solutions to meet your requirements.

What do you need to start laser business?

Starting a laser business requires careful planning and consideration of several key factors. To establish a successful venture in the laser industry, you will need to invest in high-quality industrial laser equipment suitable for your specific applications. Additionally, acquiring the necessary technical expertise and training to operate the equipment safely and efficiently is crucial. Developing a solid business plan that outlines your target market, pricing strategy, marketing approach, and financial projections is essential for long-term success. Building strong relationships with suppliers, customers, and industry partners can also help you navigate the competitive landscape of the laser business. Lastly, staying informed about industry trends, regulations, and technological advancements will enable you to stay ahead in this dynamic field.

No Responses