The Power and Precision of CO2 Lasers

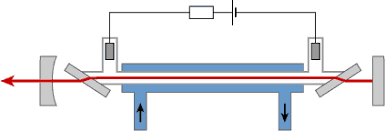

CO2 lasers are a type of gas laser that uses carbon dioxide gas as the active medium to produce a highly focused beam of infrared light. These lasers are known for their power, precision, and versatility, making them indispensable tools in a wide range of industries.

One of the key advantages of CO2 lasers is their ability to deliver high levels of energy in a concentrated beam, making them ideal for cutting, engraving, welding, and marking various materials. From metal fabrication to medical device manufacturing, CO2 lasers play a crucial role in improving efficiency and precision in industrial processes.

CO2 lasers are particularly well-suited for cutting materials such as wood, acrylic, plastic, rubber, and even some metals. The focused beam generated by these lasers can quickly and accurately cut through thick materials with minimal heat-affected zones, resulting in clean edges and precise shapes.

Another advantage of CO2 lasers is their versatility in terms of power output and beam quality. Whether you need a low-power laser for delicate engraving or a high-power laser for fast cutting operations, CO2 lasers can be tailored to meet your specific requirements.

Furthermore, advancements in CO2 laser technology have led to the development of sealed-tube lasers that require minimal maintenance and offer long operational lifetimes. This reliability makes CO2 lasers a cost-effective solution for businesses looking to enhance their manufacturing processes.

In conclusion, CO2 lasers represent a powerful and precise tool that continues to drive innovation across various industries. With their ability to deliver high-energy beams with exceptional accuracy, CO2 lasers are essential for achieving superior results in cutting-edge manufacturing applications.

Understanding CO2 Lasers: Evaluating the Cons, Common Uses, and Value of Laser Resurfacing

- What is the downside of CO2 laser resurfacing?

- What are the disadvantages of CO2 lasers?

- What is a CO2 laser used for?

- Is CO2 laser worth it?

What is the downside of CO2 laser resurfacing?

One common downside of CO2 laser resurfacing is the potential for prolonged downtime and recovery period. While CO2 lasers are highly effective in treating skin concerns such as wrinkles, scars, and pigmentation issues, the procedure can result in significant redness, swelling, and peeling of the skin post-treatment. Patients undergoing CO2 laser resurfacing may need to plan for several days to weeks of recovery time, during which they may experience discomfort and have to follow strict post-care instructions to ensure optimal healing and results. It is essential for individuals considering CO2 laser resurfacing to weigh the benefits against the potential downtime and make an informed decision based on their specific needs and lifestyle constraints.

What are the disadvantages of CO2 lasers?

While CO2 lasers offer numerous advantages in terms of power and precision, they also come with certain disadvantages that should be considered. One common drawback of CO2 lasers is their limited absorption by some materials, particularly metals with highly reflective surfaces. This can result in reduced cutting efficiency and slower processing speeds for certain applications. Additionally, CO2 lasers tend to have higher operating costs compared to other types of lasers, primarily due to the need for specialized gas refills and maintenance requirements. Despite these limitations, advancements in CO2 laser technology continue to address these challenges, making them a valuable tool in various industries.

What is a CO2 laser used for?

A CO2 laser is a versatile tool widely used across industries for various applications such as cutting, engraving, welding, and marking materials like wood, acrylic, plastic, rubber, and certain metals. Its ability to deliver a highly focused beam of infrared light makes it ideal for precision tasks where clean edges and intricate designs are required. From industrial manufacturing processes to medical device fabrication and artistic creations, CO2 lasers play a crucial role in enhancing efficiency and achieving high-quality results in a wide range of applications.

Is CO2 laser worth it?

The question of whether CO2 lasers are worth it is a common one among individuals considering investing in laser technology. The answer largely depends on the specific needs and goals of the user. CO2 lasers are renowned for their power, precision, and versatility, making them invaluable tools in a wide range of industries. From cutting and engraving to welding and marking, CO2 lasers offer exceptional performance and efficiency. Their ability to deliver high levels of energy in a focused beam, coupled with their versatility in power output and beam quality, makes them a preferred choice for many applications. Ultimately, the decision to invest in a CO2 laser comes down to weighing the benefits it offers against the specific requirements of the user’s projects and operations.

No Responses