The Power of Precision: Rotary Laser Cutters

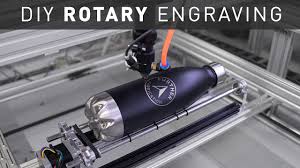

Rotary laser cutters are revolutionizing the world of precision cutting with their advanced technology and unmatched accuracy. These cutting-edge machines utilize a rotating laser beam to create intricate designs and precise cuts on a variety of materials, from paper and fabric to metal and wood.

One of the key advantages of rotary laser cutters is their ability to produce consistent results with minimal margin for error. The rotating laser beam ensures a smooth and continuous cutting process, resulting in clean edges and intricate details that are impossible to achieve with traditional cutting methods.

Whether you’re a hobbyist looking to create intricate crafts or a professional seeking to streamline your production process, rotary laser cutters offer unparalleled precision and efficiency. With their customizable settings and user-friendly interface, these machines empower users to bring their creative visions to life with ease.

In addition to their precision cutting capabilities, rotary laser cutters are also known for their versatility. They can effortlessly switch between different materials and thicknesses, making them ideal for a wide range of applications across various industries.

As technology continues to evolve, rotary laser cutters remain at the forefront of innovation in the world of cutting-edge machinery. Their ability to deliver high-quality results quickly and efficiently makes them an indispensable tool for anyone looking to elevate their craftsmanship and productivity.

Experience the power of precision with rotary laser cutters – where creativity meets technology in perfect harmony.

Everything You Need to Know About Rotary Laser Cutters: Top FAQs Answered

- What is a rotary laser cutter?

- How does a rotary laser cutter work?

- What materials can be cut with a rotary laser cutter?

- What are the advantages of using a rotary laser cutter?

- Are rotary laser cutters suitable for both professional and hobbyist use?

- What features should I look for when choosing a rotary laser cutter?

- How do I maintain and calibrate a rotary laser cutter for optimal performance?

What is a rotary laser cutter?

A rotary laser cutter is a cutting-edge machine that utilizes a rotating laser beam to achieve precise and intricate cuts on various materials. This innovative technology allows for consistent and clean cutting results, making it a popular choice for both hobbyists and professionals. With its ability to handle different materials and thicknesses, a rotary laser cutter offers unparalleled precision and versatility in the world of cutting machinery. Whether you’re looking to create detailed crafts or streamline your production process, a rotary laser cutter is a powerful tool that combines advanced technology with exceptional accuracy.

How does a rotary laser cutter work?

A rotary laser cutter operates by utilizing a rotating laser beam to precisely cut through various materials. The laser beam is emitted from a source and directed onto the material being cut, while the rotary mechanism ensures a continuous and smooth cutting process. As the material moves along the cutting path, the laser beam follows, creating intricate designs and clean edges with remarkable accuracy. This advanced technology allows for precise cuts on a wide range of materials, making rotary laser cutters an essential tool for achieving intricate and detailed results in various industries.

What materials can be cut with a rotary laser cutter?

A rotary laser cutter is a versatile tool capable of cutting a wide range of materials with precision and efficiency. Common materials that can be cut with a rotary laser cutter include paper, cardboard, acrylic, wood, leather, fabric, and certain types of plastics. The rotating laser beam allows for intricate designs and clean cuts on various thicknesses of materials, making it ideal for both hobbyists and professionals seeking to create detailed projects across different industries. With the ability to switch between materials seamlessly, rotary laser cutters offer endless possibilities for creative expression and production capabilities.

What are the advantages of using a rotary laser cutter?

When it comes to the advantages of using a rotary laser cutter, precision and efficiency are at the forefront. These cutting-edge machines offer unparalleled accuracy, ensuring clean edges and intricate details that are difficult to achieve with traditional cutting methods. The continuous rotation of the laser beam results in consistent and flawless cuts, making them ideal for a wide range of materials and applications. Additionally, rotary laser cutters are known for their versatility, allowing users to switch between different materials and thicknesses with ease. Whether you’re a hobbyist or a professional, these machines empower you to bring your creative visions to life with precision and speed.

Are rotary laser cutters suitable for both professional and hobbyist use?

Rotary laser cutters are highly versatile tools that cater to both professional and hobbyist needs with equal efficacy. Their advanced technology and precision cutting capabilities make them ideal for professionals seeking to streamline their production processes and achieve impeccable results consistently. At the same time, rotary laser cutters offer user-friendly interfaces and customizable settings that empower hobbyists to unleash their creativity and bring intricate designs to life with ease. Whether you’re a seasoned professional looking to boost efficiency or a passionate hobbyist exploring new creative avenues, rotary laser cutters are a valuable asset that caters to a wide range of users across different skill levels and industries.

What features should I look for when choosing a rotary laser cutter?

When considering a rotary laser cutter, several key features should be taken into account to ensure you select the right machine for your needs. Firstly, look for cutting precision and accuracy, as this is crucial for achieving intricate designs and clean cuts. Additionally, consider the cutting speed and power of the machine to determine its efficiency in handling various materials. Ease of use and customization options are also important factors to look for, as they can enhance your user experience and allow for greater flexibility in your projects. Lastly, pay attention to the durability and reliability of the rotary laser cutter to ensure long-term performance and value for your investment. By evaluating these features carefully, you can confidently choose a rotary laser cutter that meets your requirements and helps you achieve exceptional results in your cutting endeavors.

How do I maintain and calibrate a rotary laser cutter for optimal performance?

Maintaining and calibrating a rotary laser cutter is essential for ensuring optimal performance and longevity of the machine. Regular maintenance tasks include cleaning the lenses and mirrors to prevent dust buildup, checking and adjusting the alignment of the laser beam, and inspecting the cutting bed for any signs of wear or damage. Calibration involves fine-tuning the settings of the cutter to ensure accurate cutting depth and precision. It is recommended to follow the manufacturer’s guidelines for maintenance schedules and calibration procedures to keep your rotary laser cutter operating at its best. By investing time in proper maintenance and calibration, you can maximize the efficiency and accuracy of your machine, ultimately enhancing your cutting results and overall productivity.

No Responses