The Versatility and Precision of Nd:YAG Lasers

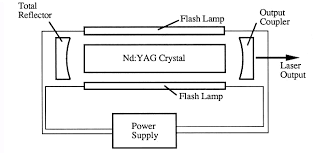

Nd:YAG lasers, short for neodymium-doped yttrium aluminum garnet lasers, are a type of solid-state laser known for their versatility and precision in various applications. These lasers utilize a crystal rod as the gain medium, which is doped with neodymium ions to produce laser light at a wavelength of 1064 nanometers in the infrared spectrum.

One of the key advantages of Nd:YAG lasers is their ability to deliver high energy pulses with exceptional beam quality. This makes them ideal for cutting, welding, engraving, and marking a wide range of materials, including metals, ceramics, plastics, and semiconductors.

Medical professionals also harness the power of Nd:YAG lasers for various procedures, such as dermatology treatments, ophthalmic surgeries, and dental applications. The precise targeting and minimal thermal damage offered by these lasers make them invaluable tools in the medical field.

Furthermore, Nd:YAG lasers find extensive use in scientific research, telecommunications, defense systems, and industrial manufacturing processes. Their reliability, efficiency, and long operational lifetimes make them a preferred choice for demanding applications that require consistent performance.

As technology continues to advance, Nd:YAG lasers remain at the forefront of innovation due to their adaptability and effectiveness across diverse industries. From intricate micro-machining to non-invasive medical procedures, these lasers continue to redefine what is achievable with laser technology.

In conclusion, Nd:YAG lasers stand as a testament to the remarkable capabilities of solid-state laser systems. With their unparalleled precision and versatility, these lasers continue to drive progress in fields ranging from manufacturing to healthcare. Their impact on modern society underscores the enduring importance of innovation in laser technology.

Six Advantages of Nd:YAG Lasers: High-Efficiency Processing, Precision Cutting, Versatile Industry Use, Reduced Medical Thermal Damage, Reliable Longevity, and Technological Adaptability

- High energy pulses for efficient material processing

- Exceptional beam quality for precise cutting and welding

- Versatile applications across various industries

- Minimal thermal damage during medical procedures

- Reliable performance with long operational lifetimes

- Adaptability to changing technological advancements

Six Drawbacks of Nd:YAG Lasers: From Cost to Versatility Limitations

- Higher initial cost compared to some other types of lasers

- Require regular maintenance and calibration to ensure optimal performance

- Limited effectiveness on certain materials with high reflectivity or transparency

- Can produce heat-affected zones in some applications, requiring additional cooling measures

- Bulkier and heavier than some compact laser systems, limiting portability

- Operate at a single wavelength, which may not be suitable for all applications requiring different wavelengths

High energy pulses for efficient material processing

YAG lasers offer a significant advantage in efficient material processing due to their capability to deliver high energy pulses. This feature allows for rapid and precise cutting, welding, engraving, and marking of various materials, making Nd:YAG lasers indispensable in industrial applications. The ability to generate intense energy pulses with exceptional beam quality not only enhances the speed of material processing but also ensures consistent and reliable results, making Nd:YAG lasers a preferred choice for tasks that demand efficiency and precision.

Exceptional beam quality for precise cutting and welding

YAG lasers are renowned for their exceptional beam quality, making them the preferred choice for precise cutting and welding tasks. The high energy pulses generated by Nd:YAG lasers ensure a focused and stable beam that enables accurate material processing with minimal heat-affected zones. This level of precision is crucial in industries where intricate cuts and welds are required, such as aerospace, automotive, and electronics manufacturing. The ability of Nd:YAG lasers to deliver consistent and reliable performance results in superior quality finished products, making them indispensable tools for achieving exacting standards in industrial applications.

Versatile applications across various industries

The versatility of Nd:YAG lasers across various industries is a testament to their exceptional adaptability and performance. From precision cutting and welding in manufacturing to non-invasive medical procedures and scientific research, Nd:YAG lasers continue to showcase their effectiveness in diverse applications. Their ability to deliver high energy pulses with outstanding beam quality makes them indispensable tools for professionals seeking reliable and precise laser solutions across a wide range of industrial sectors.

Minimal thermal damage during medical procedures

YAG lasers offer a significant advantage in medical procedures due to their ability to minimize thermal damage. This key feature allows medical professionals to precisely target tissues or areas of interest with minimal impact on surrounding healthy tissue. By delivering focused energy pulses with precision, Nd:YAG lasers enable safer and more effective treatments in dermatology, ophthalmology, and other medical fields where minimizing thermal damage is crucial for successful outcomes and patient comfort.

Reliable performance with long operational lifetimes

One of the standout advantages of Nd:YAG lasers is their reliable performance and long operational lifetimes. These lasers are renowned for their durability and consistency, making them a trusted choice for applications that demand uninterrupted operation over extended periods. The robust design and stable output of Nd:YAG lasers ensure that they can deliver high-quality results consistently, providing users with a cost-effective solution that stands the test of time.

Adaptability to changing technological advancements

The adaptability of Nd:YAG lasers to changing technological advancements is a key advantage that sets them apart in the realm of laser technology. These lasers have consistently proven their ability to evolve and integrate seamlessly with emerging innovations, making them a reliable choice for industries at the forefront of technological progress. Whether it’s incorporating new materials, enhancing precision capabilities, or expanding into novel applications, Nd:YAG lasers demonstrate a remarkable flexibility that ensures they remain relevant and effective in an ever-changing landscape of technological advancements.

Higher initial cost compared to some other types of lasers

One notable drawback of Nd:YAG lasers is their higher initial cost when compared to certain other types of lasers available in the market. The investment required to acquire and set up Nd:YAG laser systems can be a significant consideration for businesses or individuals looking to integrate laser technology into their operations. While the precision and versatility of Nd:YAG lasers are undeniable, the upfront financial commitment may pose a challenge for those operating within budget constraints or seeking more cost-effective laser solutions.

Require regular maintenance and calibration to ensure optimal performance

One notable drawback of Nd:YAG lasers is their requirement for regular maintenance and calibration to uphold optimal performance levels. This necessitates dedicated time and resources to ensure that the laser system functions at its peak efficiency. Failure to adhere to a strict maintenance schedule can result in diminished output quality, reduced reliability, and potential downtime, highlighting the importance of ongoing care and attention to detail when utilizing Nd:YAG lasers in various applications.

Limited effectiveness on certain materials with high reflectivity or transparency

One notable limitation of Nd:YAG lasers is their reduced effectiveness when it comes to processing materials with high reflectivity or transparency. Due to the nature of these materials, the laser beam may struggle to be absorbed efficiently, leading to suboptimal results in cutting, welding, or engraving processes. This challenge poses a hurdle for applications that involve highly reflective metals or transparent substances, requiring alternative laser sources or techniques to achieve desired outcomes effectively.

Can produce heat-affected zones in some applications, requiring additional cooling measures

In certain applications, a notable drawback of Nd:YAG lasers is their tendency to produce heat-affected zones, which can potentially affect the quality of the material being processed. This necessitates the implementation of additional cooling measures to mitigate the heat buildup and minimize thermal damage. While Nd:YAG lasers offer high precision and power, the challenge of managing heat-affected zones underscores the importance of careful planning and control in ensuring optimal outcomes in various laser processing tasks.

Bulkier and heavier than some compact laser systems, limiting portability

YAG lasers, while renowned for their power and precision, do have a drawback in terms of portability due to their bulkier and heavier design compared to some compact laser systems. This limitation can restrict the ease of transportation and deployment in certain settings where space or mobility is a concern. Despite this con, the exceptional performance and versatility of Nd:YAG lasers often outweigh the inconvenience of their larger size, making them a preferred choice for applications where portability is not a primary consideration.

Operate at a single wavelength, which may not be suitable for all applications requiring different wavelengths

One limitation of Nd:YAG lasers is their operation at a single wavelength, typically 1064 nanometers in the infrared spectrum. This can pose a challenge for applications that demand different wavelengths for optimal performance. In scenarios where specific wavelengths are required for tasks such as material processing, medical treatments, or scientific research, the fixed wavelength of Nd:YAG lasers may not be suitable. This constraint underscores the importance of considering the specific needs of each application and exploring alternative laser technologies that offer a broader range of wavelengths to address diverse requirements effectively.

No Responses