The Power of Laser Marking Systems

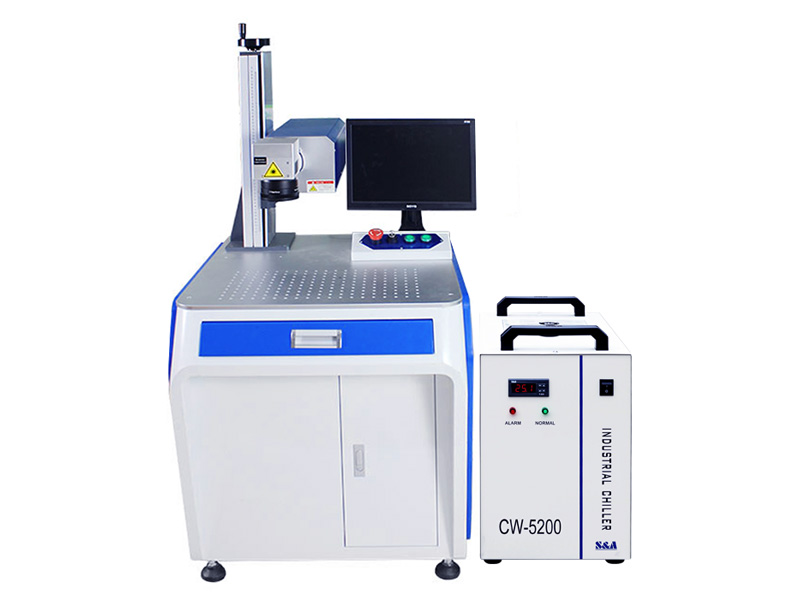

When it comes to marking and engraving materials with precision and efficiency, laser marking systems are at the forefront of technology. These advanced systems utilize laser beams to create permanent marks on a variety of surfaces, offering numerous benefits across different industries.

One of the key advantages of laser marking systems is their versatility. Whether you need to mark metal, plastic, glass, or even organic materials, laser systems can deliver high-quality results with exceptional accuracy. This makes them ideal for applications in automotive, aerospace, electronics, medical devices, and more.

Another significant benefit of laser marking systems is their non-contact process. Unlike traditional methods such as etching or stamping, laser marking does not require direct contact with the material being marked. This reduces the risk of damage to delicate surfaces and ensures consistent results even on complex shapes and contours.

Furthermore, laser marking systems offer unmatched speed and precision. With the ability to control parameters such as power, speed, and focus, operators can achieve precise markings with minimal margin for error. This level of control allows for customization and personalization, making laser marking systems a popular choice for branding and product identification.

In addition to their efficiency and accuracy, laser marking systems are also environmentally friendly. By using focused laser beams to create marks without the need for consumables such as inks or solvents, these systems reduce waste and minimize environmental impact. This aligns with the growing trend towards sustainable manufacturing practices.

Overall, the power of laser marking systems lies in their ability to deliver reliable and consistent results across a wide range of materials and applications. As technology continues to advance, these systems will play an increasingly important role in modern manufacturing processes, driving innovation and efficiency in various industries.

6 Essential Tips for Optimal Use and Maintenance of Your Laser Marking System

- Ensure proper maintenance of the laser marking system for optimal performance.

- Regularly calibrate the system to maintain accuracy and consistency in marking.

- Use the appropriate settings such as power, speed, and frequency for different materials.

- Implement safety measures to protect operators from potential hazards associated with laser technology.

- Keep the work area clean and free of debris to prevent interference with the marking process.

- Train operators on how to use the laser marking system effectively and safely.

Ensure proper maintenance of the laser marking system for optimal performance.

To ensure optimal performance of your laser marking system, it is crucial to prioritize proper maintenance. Regular maintenance tasks such as cleaning optical components, checking for alignment issues, and monitoring system parameters can help prevent downtime and ensure consistent results. By investing time and effort in maintaining your laser marking system, you can prolong its lifespan, maximize efficiency, and ultimately achieve the best possible outcomes for your marking applications.

Regularly calibrate the system to maintain accuracy and consistency in marking.

Regular calibration of a laser marking system is essential to ensure precision and consistency in the marking process. By regularly calibrating the system, operators can maintain the accuracy of the laser beam focus, power settings, and other parameters that directly impact the quality of the marks produced. This proactive approach not only helps prevent errors and inconsistencies but also prolongs the lifespan of the equipment, ultimately maximizing efficiency and productivity in various industrial applications.

Use the appropriate settings such as power, speed, and frequency for different materials.

To achieve optimal results with a laser marking system, it is essential to use the appropriate settings tailored to the specific material being marked. Factors such as power, speed, and frequency play a crucial role in determining the quality and precision of the mark. By adjusting these settings according to the material properties, operators can ensure consistent and reliable markings that meet the desired specifications. This attention to detail not only enhances efficiency but also extends the lifespan of the equipment, making it a key practice in maximizing the performance of laser marking systems.

Implement safety measures to protect operators from potential hazards associated with laser technology.

It is crucial to implement stringent safety measures to safeguard operators from potential hazards linked to laser technology. By providing proper training, ensuring the use of protective gear, and establishing clear protocols for handling laser marking systems, companies can minimize the risk of accidents and protect the well-being of their employees. Prioritizing safety not only complies with regulatory standards but also fosters a secure working environment where operators can confidently harness the power of laser technology for efficient and precise marking applications.

Keep the work area clean and free of debris to prevent interference with the marking process.

To ensure optimal performance of your laser marking system, it is crucial to maintain a clean and debris-free work area. Keeping the work area free of dust, dirt, and other contaminants helps prevent interference with the marking process, ensuring that the laser can create precise and accurate marks on the material. By maintaining a clean environment, you can maximize the efficiency and effectiveness of your laser marking system, leading to consistent and high-quality results.

Train operators on how to use the laser marking system effectively and safely.

Training operators on how to effectively and safely use a laser marking system is crucial for ensuring optimal performance and minimizing risks in the workplace. By providing comprehensive training on operating procedures, safety protocols, and maintenance practices, operators can confidently utilize the system to its full potential while prioritizing their well-being and that of others. Proper training not only enhances productivity and quality but also instills a culture of responsibility and professionalism among operators, leading to a safer and more efficient work environment.

No Responses