The Versatility of Honeycomb for Laser Cutters

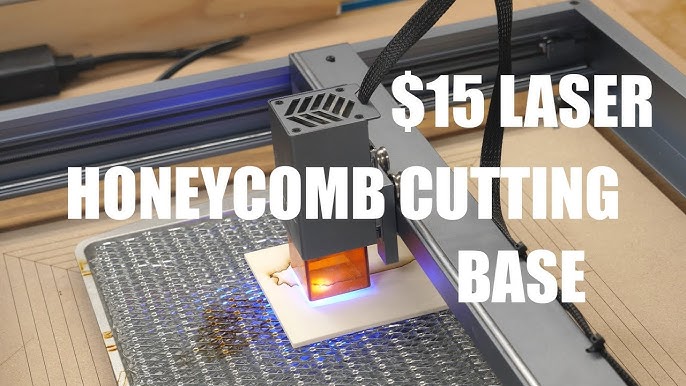

When it comes to laser cutting, precision and efficiency are key. One essential accessory that plays a crucial role in optimizing the performance of a laser cutter is the honeycomb bed.

A honeycomb bed consists of a grid-like structure made of aluminum or stainless steel with hexagonal cells that allow air to flow freely while providing sturdy support for the material being cut. This unique design helps prevent back reflections and ensures that the material remains flat and undamaged during the cutting process.

One of the main advantages of using a honeycomb bed is its ability to reduce the risk of flare-ups and fires by allowing smoke and debris to be quickly extracted through the cells. This not only enhances safety in the workspace but also helps maintain a clean working environment.

Moreover, the honeycomb structure minimizes contact between the material and the cutting surface, reducing the chances of heat transfer and resulting in cleaner cuts with minimal residue. This is particularly beneficial when working with delicate materials or intricate designs that require high precision.

Another advantage of using a honeycomb bed is its versatility. The grid pattern allows for easy customization and adjustment, making it suitable for various materials and thicknesses. Whether you’re cutting wood, acrylic, leather, or fabric, a honeycomb bed can provide consistent results across different applications.

In conclusion, incorporating a honeycomb bed into your laser cutter setup can significantly improve efficiency, safety, and overall cutting quality. Its unique design offers unmatched versatility and precision, making it an indispensable accessory for any laser cutting operation.

Top 6 Benefits of Using Honeycomb for Laser Cutting: Precision, Safety, and Versatility

- Enhances cutting precision by providing a flat and stable surface for materials.

- Reduces the risk of flare-ups and fires by allowing efficient smoke and debris extraction.

- Minimizes heat transfer to materials, resulting in cleaner cuts with minimal residue.

- Versatile design accommodates various materials and thicknesses for diverse cutting applications.

- Promotes safety in the workspace by preventing back reflections during the cutting process.

- Easy to customize and adjust, offering flexibility and adaptability for different cutting needs.

Challenges of Using Honeycomb Beds in Laser Cutting: A Closer Look at Limitations and Maintenance

- 1. Limited thickness capacity for materials that can be used due to the height of the honeycomb bed.

- 2. Honeycomb structure may leave imprints on softer materials, affecting the final finish.

- 3. Cleaning and maintenance of the honeycomb bed can be time-consuming and labor-intensive.

- 4. Cost of replacement or repair in case of damage to the honeycomb bed can be relatively high.

- 5. Honeycomb beds may not be suitable for cutting materials with irregular shapes or small pieces that could fall through the cells.

- 6. The weight and size of a honeycomb bed can make it challenging to handle and install, especially in smaller laser cutter models.

Enhances cutting precision by providing a flat and stable surface for materials.

The honeycomb bed for laser cutters enhances cutting precision by offering a flat and stable surface for materials. Its grid-like structure provides reliable support, ensuring that the material remains level and undisturbed during the cutting process. This stability minimizes vibrations and movement, allowing the laser to achieve precise cuts with consistent accuracy. By eliminating potential distortions caused by uneven surfaces, the honeycomb bed enables intricate designs and detailed cuts to be executed with exceptional precision and quality.

Reduces the risk of flare-ups and fires by allowing efficient smoke and debris extraction.

One notable advantage of using a honeycomb bed in a laser cutter is its ability to decrease the likelihood of flare-ups and fires by facilitating the efficient extraction of smoke and debris. The grid-like structure of the honeycomb allows for optimal airflow, ensuring that any generated smoke or debris is quickly and effectively removed from the cutting area. This not only enhances the safety of the workspace but also helps maintain a clean and controlled environment, minimizing potential hazards and disruptions during the cutting process.

Minimizes heat transfer to materials, resulting in cleaner cuts with minimal residue.

One of the key benefits of using a honeycomb bed in a laser cutter is its ability to minimize heat transfer to materials during the cutting process. This feature ensures that the material remains cool and undamaged, resulting in cleaner cuts with minimal residue. By reducing heat transfer, the honeycomb bed helps maintain the integrity of the material being cut, allowing for precise and high-quality results without any unwanted discoloration or warping.

Versatile design accommodates various materials and thicknesses for diverse cutting applications.

The versatile design of a honeycomb bed for laser cutters allows for seamless accommodation of a wide range of materials and thicknesses, making it an ideal choice for diverse cutting applications. Whether working with wood, acrylic, leather, or fabric, the honeycomb structure provides consistent support and ensures precise cutting results across different materials. This adaptability not only enhances efficiency but also expands the possibilities for creative and industrial uses of laser cutting technology.

Promotes safety in the workspace by preventing back reflections during the cutting process.

The honeycomb bed in a laser cutter plays a crucial role in promoting safety in the workspace by effectively preventing back reflections during the cutting process. This feature helps minimize the risk of flare-ups and fires by ensuring that any reflected laser energy is absorbed or diffused within the honeycomb structure, rather than bouncing back onto the material being cut. By eliminating back reflections, the honeycomb bed not only enhances the safety of operators but also helps maintain a secure and controlled working environment conducive to efficient laser cutting operations.

Easy to customize and adjust, offering flexibility and adaptability for different cutting needs.

The honeycomb bed for laser cutters stands out for its exceptional flexibility and adaptability, making it easy to customize and adjust according to different cutting requirements. This feature allows users to effortlessly switch between various materials and thicknesses, ensuring precise and consistent results across a wide range of applications. Whether cutting intricate designs on delicate fabrics or working with sturdy wood or acrylic, the honeycomb bed’s ability to adapt to different needs makes it a versatile and indispensable tool for achieving optimal cutting performance.

1. Limited thickness capacity for materials that can be used due to the height of the honeycomb bed.

One notable limitation of using a honeycomb bed in a laser cutter is its restricted thickness capacity for materials. The height of the honeycomb bed can pose a challenge when working with thicker materials, as it may not accommodate them properly for cutting. This limitation can hinder the versatility of the laser cutter, especially when dealing with materials that exceed the height clearance provided by the honeycomb bed. Users may need to explore alternative setups or consider removing the honeycomb bed altogether when working with thicker materials to ensure optimal cutting results.

2. Honeycomb structure may leave imprints on softer materials, affecting the final finish.

One notable drawback of using a honeycomb bed in a laser cutter is that its structure may leave imprints on softer materials, potentially affecting the final finish of the cut. The hexagonal cells of the honeycomb bed can sometimes create indentations or marks on delicate materials such as paper, foam, or certain types of fabric. This issue can be particularly problematic when working on projects that require a smooth and flawless surface, as the imprints left by the honeycomb structure may detract from the overall quality of the finished product. Careful consideration and testing of materials are essential to mitigate this con and ensure optimal results when using a honeycomb bed with a laser cutter.

3. Cleaning and maintenance of the honeycomb bed can be time-consuming and labor-intensive.

One notable drawback of using a honeycomb bed for laser cutters is the time-consuming and labor-intensive nature of cleaning and maintenance. The intricate grid structure of the honeycomb bed can trap debris, dust, and residue from the cutting process, requiring thorough cleaning to ensure optimal performance. This process can be tedious and may involve disassembling the bed for deep cleaning, adding to the overall maintenance workload for operators. Failure to regularly clean the honeycomb bed can lead to reduced cutting quality, increased risk of flare-ups, and potential damage to both the material being cut and the laser cutter itself.

4. Cost of replacement or repair in case of damage to the honeycomb bed can be relatively high.

One notable drawback of using a honeycomb bed for a laser cutter is the potential cost implications associated with its replacement or repair in case of damage. Due to the specialized design and materials used in honeycomb beds, the cost of sourcing a new bed or repairing existing damage can be relatively high. This factor should be taken into consideration when weighing the overall investment and maintenance expenses of utilizing a honeycomb bed in a laser cutting setup.

5. Honeycomb beds may not be suitable for cutting materials with irregular shapes or small pieces that could fall through the cells.

One notable drawback of honeycomb beds for laser cutters is that they may not be ideal for cutting materials with irregular shapes or small pieces that have the potential to fall through the cells. The grid-like structure of a honeycomb bed, while effective in providing support and airflow, can pose challenges when working with intricate designs or materials that are not uniform in shape. In such cases, there is a risk of smaller pieces slipping through the gaps in the honeycomb, leading to inconsistent cuts or potential damage to the material. Careful consideration and alternative support methods may be necessary when dealing with materials that do not align well with the design of a honeycomb bed.

6. The weight and size of a honeycomb bed can make it challenging to handle and install, especially in smaller laser cutter models.

The weight and size of a honeycomb bed can present a significant challenge when it comes to handling and installing it, particularly in smaller laser cutter models. The bulkiness of the honeycomb bed may require additional effort and manpower to maneuver and fit into place, which can be cumbersome and time-consuming. This limitation may pose practical difficulties for users who have limited space or mobility constraints, making the setup process more complex than desired.

No Responses