The Art of Glass Engraving: Unleashing Creativity with a Glass Engraving Machine

Glass engraving is a time-honored craft that adds a touch of elegance and personalization to any glass surface. Whether you’re looking to create custom gifts, decorative pieces, or intricate designs, a glass engraving machine is the perfect tool to bring your vision to life.

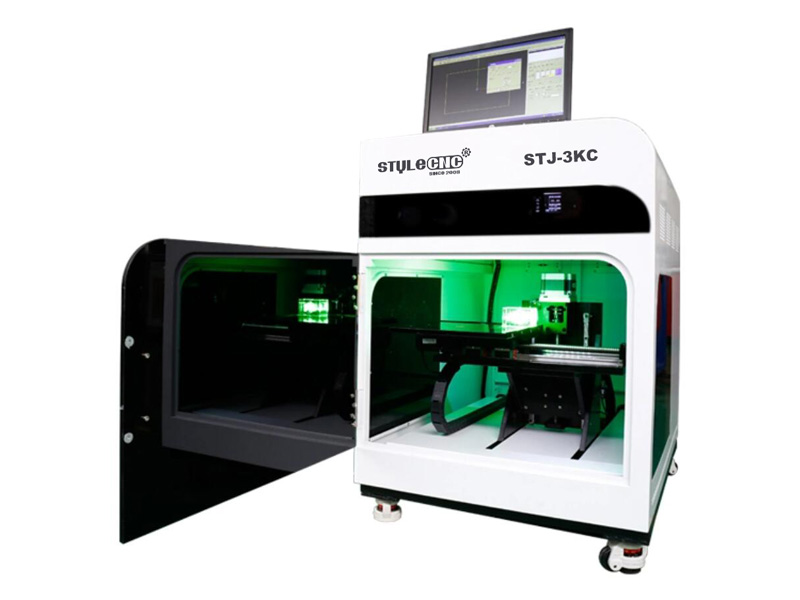

With advancements in technology, modern glass engraving machines have made the process more accessible and efficient than ever before. These machines use precision lasers or rotary tools to etch designs onto glass surfaces with incredible detail and accuracy.

One of the key benefits of using a glass engraving machine is the ability to customize your creations. From personalized wine glasses and trophies to intricate art pieces and signage, the possibilities are endless. You can unleash your creativity and express yourself through unique engravings that reflect your style and personality.

Glass engraving machines are not limited to professionals – hobbyists and DIY enthusiasts can also enjoy the art of glass engraving from the comfort of their own homes. Many machines come equipped with user-friendly software that allows you to design and execute projects with ease, making it accessible to beginners and experts alike.

Whether you’re a small business looking to offer custom engraving services or an individual wanting to add a personal touch to your home décor, a glass engraving machine is a versatile tool that opens up a world of creative possibilities.

Investing in a quality glass engraving machine can be a game-changer for artists, crafters, and businesses alike. It allows you to elevate your creations, stand out from the crowd, and make a lasting impression with unique and personalized designs etched in glass.

Explore the art of glass engraving today with a state-of-the-art glass engraving machine – where creativity knows no bounds.

9 Essential Tips for Mastering Glass Engraving with Precision and Safety

- Ensure the glass surface is clean and free of any dust or debris before engraving.

- Use a high-quality engraving tool or bit suitable for glass to achieve precise and detailed engravings.

- Adjust the engraving machine settings such as speed and depth according to the type of glass being engraved.

- Practice on scrap glass pieces to test different designs and settings before working on your final piece.

- Secure the glass properly in place to prevent any movement during the engraving process.

- Consider using a protective mask and safety goggles when operating the engraving machine to avoid inhaling glass particles or debris.

- Regularly maintain and clean your engraving machine to ensure optimal performance and longevity.

- Experiment with different techniques such as shading, line thickness, and textures to create unique engravings.

- Allow sufficient time for each engraving project, as rushing can lead to mistakes or uneven engravings.

Ensure the glass surface is clean and free of any dust or debris before engraving.

To achieve precise and flawless engravings with your glass engraving machine, it is crucial to ensure that the glass surface is thoroughly clean and free of any dust or debris before starting the engraving process. Even small particles can interfere with the engraving and result in imperfections or inconsistencies in the design. By taking the time to properly clean the glass surface, you can set the stage for a successful and professional-looking engraving that meets your expectations.

Use a high-quality engraving tool or bit suitable for glass to achieve precise and detailed engravings.

To achieve precise and detailed engravings when using a glass engraving machine, it is essential to use a high-quality engraving tool or bit specifically designed for glass. Choosing the right tool for the job ensures clean and accurate etching, allowing you to create intricate designs with sharp clarity. A suitable engraving tool will not only enhance the quality of your work but also make the engraving process smoother and more efficient, resulting in professional-looking results that truly stand out.

Adjust the engraving machine settings such as speed and depth according to the type of glass being engraved.

To achieve optimal results when using a glass engraving machine, it is crucial to adjust the machine settings, such as speed and depth, based on the type of glass being engraved. Different types of glass have varying hardness and thickness, requiring specific settings to ensure precise and clean engravings. By customizing the machine settings to match the characteristics of the glass, you can enhance the quality of your engravings and achieve stunning outcomes that meet your expectations.

Practice on scrap glass pieces to test different designs and settings before working on your final piece.

Before embarking on engraving your final piece, it is advisable to practice on scrap glass pieces to test various designs and settings. This allows you to experiment with different techniques, refine your skills, and gain confidence in using the glass engraving machine effectively. By practicing on scrap glass, you can avoid costly mistakes and ensure that your final piece turns out exactly as you envision it. Testing different designs and settings beforehand will help you achieve the desired results with precision and finesse.

Secure the glass properly in place to prevent any movement during the engraving process.

Securing the glass properly in place is crucial when using a glass engraving machine to ensure precision and accuracy in the engraving process. By preventing any movement of the glass, you can avoid potential errors or distortions in the design, resulting in a clean and flawless engraving outcome. Taking the time to secure the glass adequately not only enhances the quality of your work but also minimizes the risk of damage to both the glass and the engraving machine, allowing for a seamless and successful engraving experience.

Consider using a protective mask and safety goggles when operating the engraving machine to avoid inhaling glass particles or debris.

When operating a glass engraving machine, it is crucial to prioritize safety by considering the use of a protective mask and safety goggles. These essential safety gear items help prevent the inhalation of glass particles or debris that may be generated during the engraving process. By wearing a protective mask and safety goggles, you can safeguard your respiratory system and eyes from potential harm, ensuring a safe and secure working environment while using the engraving machine.

Regularly maintain and clean your engraving machine to ensure optimal performance and longevity.

Regular maintenance and cleaning of your glass engraving machine is essential to ensure it operates at its best and lasts for years to come. By keeping your machine well-maintained, you can prevent issues such as build-up of debris or residue that may affect its performance. Regular upkeep not only ensures optimal results but also extends the longevity of your engraving machine, allowing you to continue creating stunning glass engravings with precision and efficiency.

Experiment with different techniques such as shading, line thickness, and textures to create unique engravings.

To elevate your glass engraving creations to the next level, it’s essential to experiment with various techniques such as shading, line thickness, and textures. By exploring these different elements, you can infuse your engravings with depth, dimension, and character, resulting in truly unique and captivating designs. Play around with light and shadow through shading, vary line thickness to add emphasis and detail, and incorporate textures to create visual interest and tactile appeal. Embracing these techniques will allow you to unleash your creativity and craft engravings that stand out for their artistry and individuality.

Allow sufficient time for each engraving project, as rushing can lead to mistakes or uneven engravings.

When using a glass engraving machine, it is crucial to allow sufficient time for each project to ensure precision and quality. Rushing through the engraving process can result in mistakes or uneven engravings, diminishing the overall look and impact of your design. By taking your time and approaching each project with patience and attention to detail, you can achieve flawless results that truly showcase the beauty and artistry of glass engraving.

No Responses