The Power of DIY Laser Cutting Machines

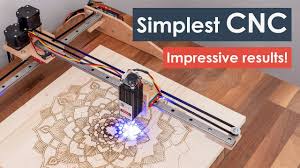

DIY laser cutting machines have revolutionized the way individuals and small businesses approach fabrication and design projects. These versatile tools offer precision cutting capabilities that were once only accessible to large manufacturers with hefty budgets.

One of the key advantages of DIY laser cutting machines is their affordability and accessibility. With the rise of open-source hardware and software, hobbyists and entrepreneurs can now build their own laser cutters at a fraction of the cost of commercial machines.

DIY laser cutting machines come in various sizes and power levels, allowing users to choose a model that suits their specific needs. From intricate woodwork to precise metal cutting, these machines offer endless possibilities for creative projects.

Moreover, DIY laser cutting machines are relatively easy to assemble and operate, thanks to detailed guides and tutorials available online. This democratization of technology empowers individuals to unleash their creativity without being limited by traditional manufacturing constraints.

Whether you’re a maker looking to bring your designs to life or a small business seeking cost-effective production solutions, a DIY laser cutting machine can be a game-changer. The ability to create custom products with speed and precision opens up new opportunities for innovation and entrepreneurship.

In conclusion, DIY laser cutting machines represent a powerful tool for makers, designers, and entrepreneurs alike. By combining affordability, accessibility, and precision, these machines are reshaping the landscape of modern fabrication and design.

DIY Laser Cutting Machines: Capabilities, Profitability, Costs, and Limitations

- What can a 1000w laser-cut?

- Is laser cutting profitable?

- How much is a DIY laser cutter?

- What Cannot be cut with a laser cutter?

What can a 1000w laser-cut?

The power of a 1000W laser cutting machine opens up a wide range of possibilities in terms of materials that can be cut with precision. With such high wattage, a 1000W laser cutter can effectively cut through various materials including metals like stainless steel, aluminum, and mild steel. Additionally, it can be used to cut acrylic, wood, plastic, and even some types of ceramics. The versatility and power of a 1000W laser cutting machine make it a valuable tool for both hobbyists and professionals looking to create intricate designs and precise cuts across different materials.

Is laser cutting profitable?

The question of whether laser cutting is profitable is a common one among individuals considering investing in a DIY laser cutting machine. The profitability of laser cutting depends on various factors, including the initial cost of the machine, material costs, operating expenses, and market demand for laser-cut products. While there is potential for significant profit margins with laser cutting due to its precision and versatility, success often hinges on factors such as efficient production processes, quality control, pricing strategies, and effective marketing. By carefully analyzing these variables and tailoring your approach to the specific needs of your target market, you can maximize the profitability of your DIY laser cutting venture.

How much is a DIY laser cutter?

The cost of a DIY laser cutter can vary depending on factors such as the size, power, and complexity of the machine. Generally, DIY laser cutter kits can range from a few hundred dollars to a couple of thousand dollars. It’s important to consider not only the upfront cost of the machine but also any additional expenses for materials, maintenance, and upgrades. Investing in a DIY laser cutter can be a cost-effective solution for individuals and small businesses looking to harness the power of precision cutting technology without breaking the bank.

What Cannot be cut with a laser cutter?

When it comes to the capabilities of a DIY laser cutting machine, there are certain materials that cannot be cut effectively or safely with a laser cutter. For instance, materials such as PVC and vinyl can release toxic fumes when subjected to the intense heat of a laser beam, making them unsuitable for laser cutting. Similarly, reflective surfaces like metals can reflect the laser beam and damage the machine or create inconsistent cuts. Understanding the limitations of a laser cutter is crucial for achieving optimal results and ensuring both the safety of the operator and the longevity of the equipment.

No Responses