The Power of Customized Laser Technology

In today’s rapidly evolving technological landscape, customized laser technology has emerged as a game-changer across various industries. From precision cutting in manufacturing to intricate engraving in the arts, the versatility and efficiency of customized lasers have revolutionized the way we approach a wide range of applications.

One of the key benefits of customized laser technology is its ability to tailor solutions to meet specific needs. By fine-tuning parameters such as wavelength, power output, and beam quality, businesses can optimize their processes for maximum efficiency and effectiveness. This level of customization allows for greater precision and control, leading to superior results in a variety of tasks.

Manufacturers, for example, can benefit from customized laser systems that are designed to cut through various materials with unparalleled accuracy. By adjusting the laser settings to match the properties of the material being processed, manufacturers can achieve cleaner cuts, reduced waste, and higher productivity levels.

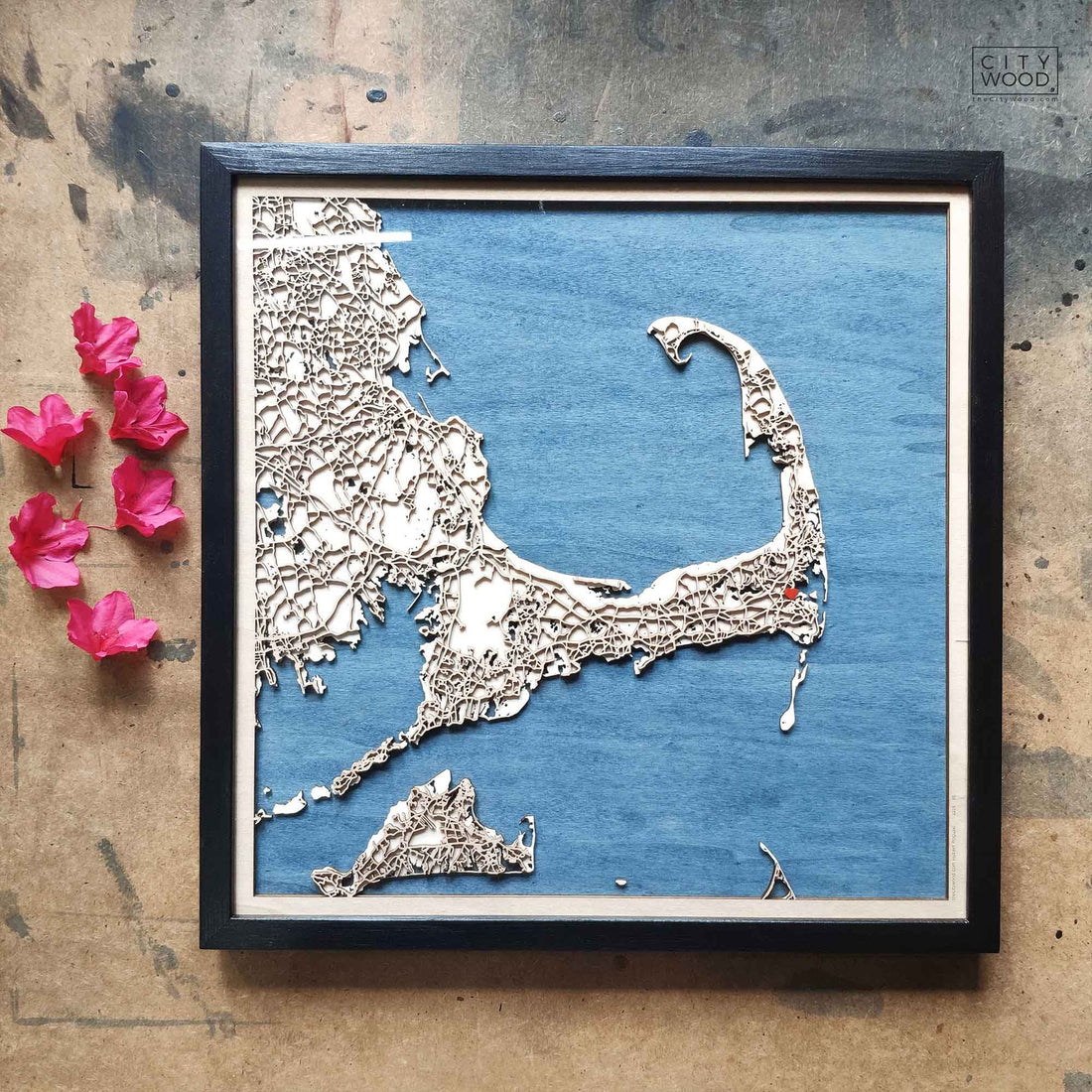

Similarly, artists and designers can leverage customized laser engraving systems to bring their creative visions to life with exceptional detail and clarity. Whether etching intricate patterns on metal surfaces or personalizing products with custom designs, the precision offered by customized lasers opens up a world of possibilities for artistic expression.

Moreover, the versatility of customized laser technology extends beyond traditional applications. From medical devices and electronics manufacturing to entertainment and research fields, lasers can be tailored to address specific challenges and requirements unique to each industry.

As advancements in laser technology continue to push boundaries and unlock new capabilities, the demand for customized solutions is expected to grow exponentially. Businesses that invest in tailored laser systems stand to gain a competitive edge by enhancing their operational efficiency, product quality, and overall performance.

In conclusion, customized laser technology represents a powerful tool for driving innovation and unlocking new possibilities across diverse industries. By harnessing the potential of custom-designed laser systems, businesses can elevate their processes, products, and services to new heights of excellence.

9 Essential Tips for Customizing Laser Projects Safely and Effectively

- Consult with a professional to determine the best laser type for your specific needs.

- Consider the materials you will be working with when choosing a laser wavelength.

- Ensure proper ventilation in your workspace to safely remove fumes and particles produced during laser cutting or engraving.

- Regularly clean and maintain your laser machine to ensure optimal performance and longevity.

- Experiment with different settings to achieve the desired depth and quality of cuts or engravings.

- Use appropriate safety gear, such as goggles, when operating a laser machine to protect your eyes from potential harm.

- Always double-check your design files before starting a laser project to avoid errors or misprints.

- Calibrate your laser machine regularly to maintain accuracy in cutting and engraving tasks.

- Consider adding a rotary attachment for cylindrical objects to expand the versatility of your laser machine.

Consult with a professional to determine the best laser type for your specific needs.

When considering customized laser technology for your applications, it is crucial to consult with a professional to determine the best laser type for your specific needs. A professional can provide valuable insights based on their expertise and experience, helping you select the most suitable laser system that aligns with your requirements and objectives. By seeking guidance from a knowledgeable specialist, you can ensure that your investment in customized laser technology yields optimal results and enhances the efficiency and effectiveness of your processes.

Consider the materials you will be working with when choosing a laser wavelength.

When selecting a laser wavelength for customized laser applications, it is crucial to consider the materials you will be working with. Different materials interact uniquely with specific wavelengths of light, affecting the cutting, engraving, or marking process. By matching the laser wavelength to the material properties, you can optimize precision and efficiency, ensuring superior results in your laser processing tasks.

Ensure proper ventilation in your workspace to safely remove fumes and particles produced during laser cutting or engraving.

To ensure a safe working environment when using customized laser technology, it is crucial to prioritize proper ventilation in your workspace. The fumes and particles generated during laser cutting or engraving processes can pose health risks if not effectively removed from the air. By implementing adequate ventilation systems, such as exhaust fans or air filtration units, you can minimize exposure to harmful emissions and maintain a clean and healthy workspace for both operators and equipment. Prioritizing ventilation not only enhances safety but also promotes optimal performance and longevity of your customized laser system.

Regularly clean and maintain your laser machine to ensure optimal performance and longevity.

Regularly cleaning and maintaining your laser machine is essential to ensure optimal performance and longevity. By keeping the machine free from dust, debris, and residue buildup, you can prevent potential issues such as decreased cutting or engraving quality, overheating, and component wear. Routine maintenance tasks like cleaning lenses, mirrors, and filters, as well as checking for loose connections or worn parts, can help extend the lifespan of your laser machine and maximize its efficiency. Investing time in proper upkeep not only safeguards the performance of your equipment but also contributes to achieving consistent results and reducing downtime in your operations.

Experiment with different settings to achieve the desired depth and quality of cuts or engravings.

To optimize the performance of customized laser systems, it is essential to experiment with various settings to achieve the desired depth and quality of cuts or engravings. By adjusting parameters such as power output, speed, and focal length, users can fine-tune their laser settings to meet specific requirements for different materials and applications. This hands-on approach not only allows for greater precision and control but also enables individuals to unlock the full potential of customized lasers in producing high-quality results that align perfectly with their unique needs and preferences.

Use appropriate safety gear, such as goggles, when operating a laser machine to protect your eyes from potential harm.

When working with customized laser technology, it is crucial to prioritize safety by using appropriate protective gear, such as goggles, to safeguard your eyes from potential harm. Laser machines emit powerful beams that can cause serious eye damage if proper precautions are not taken. By wearing protective goggles designed for laser work, you can minimize the risk of injury and ensure a safe working environment for yourself and those around you. Remember, protecting your eyes is essential when operating a laser machine to prevent any accidents or long-term health consequences.

Always double-check your design files before starting a laser project to avoid errors or misprints.

To ensure a successful laser project, it is crucial to always double-check your design files before initiating the process. By carefully reviewing your design files for accuracy and completeness, you can mitigate the risk of errors or misprints that could compromise the final outcome. Taking this extra step of verification not only saves time and resources but also helps maintain the integrity and quality of your laser project.

Calibrate your laser machine regularly to maintain accuracy in cutting and engraving tasks.

To ensure precision and consistency in cutting and engraving tasks with your customized laser machine, it is crucial to calibrate the equipment regularly. By calibrating the laser machine at scheduled intervals, you can maintain its accuracy and performance levels, resulting in clean cuts and detailed engravings. Regular calibration helps to fine-tune the settings of the laser system, ensuring that it operates at optimal efficiency and delivers reliable results across various materials and applications.

Consider adding a rotary attachment for cylindrical objects to expand the versatility of your laser machine.

Consider enhancing the versatility of your laser machine by incorporating a rotary attachment specifically designed for cylindrical objects. By adding this accessory, you can expand the range of items that your laser can work on, such as cups, bottles, and other rounded surfaces. This simple addition not only increases the functionality of your machine but also opens up a whole new world of creative possibilities for personalized designs and intricate engravings on cylindrical objects.

No Responses