The Art of Copper Laser Engraving

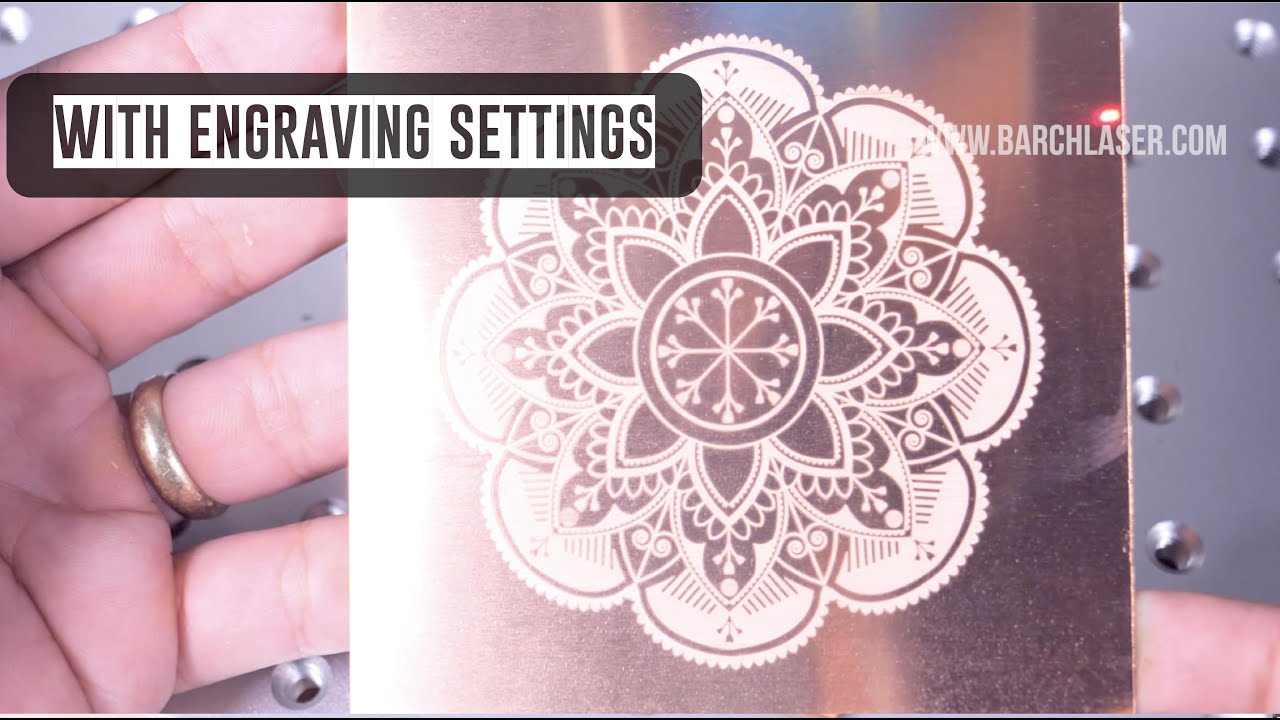

When it comes to creating intricate designs on metal, copper laser engraving stands out as a precise and versatile technique. Utilizing the power of lasers, artisans can etch detailed patterns, text, and images onto copper surfaces with incredible accuracy and speed.

One of the key advantages of copper laser engraving is the ability to achieve fine details that may be challenging with traditional engraving methods. The focused beam of the laser can create intricate designs with sharp edges and smooth finishes, adding a touch of elegance to any project.

Another benefit of using lasers for engraving copper is the speed at which the process can be completed. Unlike manual engraving techniques that require time-consuming handwork, laser engraving can swiftly etch designs onto copper surfaces with precision and consistency.

Furthermore, copper laser engraving offers a high level of customization. Artisans can easily adjust settings to control the depth and intensity of the engraving, allowing for a range of effects from subtle shading to deep relief. This flexibility enables artists to bring their creative visions to life on copper in ways that were once unimaginable.

Whether used for creating personalized gifts, custom jewelry, or decorative art pieces, copper laser engraving opens up a world of possibilities for artisans and designers. The marriage of traditional craftsmanship with cutting-edge technology results in stunning creations that captivate the eye and inspire awe.

In conclusion, copper laser engraving is a transformative technique that elevates metalworking to new heights. Its precision, speed, and versatility make it an invaluable tool for artists seeking to push boundaries and explore the endless potential of metal as a medium for artistic expression.

Top 5 Benefits of Copper Laser Engraving: Precision, Speed, and Quality

- Precise and detailed engraving

- Fast and efficient process

- Versatile customization options

- Ability to create intricate designs with sharp edges

- High-quality finishes on copper surfaces

Challenges of Copper Laser Engraving: Costs, Complexity, and Maintenance

- Initial setup costs for copper laser engraving equipment can be high.

- Copper is a highly reflective material, which may require specialized techniques to optimize engraving quality.

- Laser engraving on copper can produce heat-affected zones that may affect the appearance of the final design.

- Complex designs with fine details may take longer to engrave on copper, increasing production time and cost.

- Copper laser engraving may emit fumes or odors during the process, requiring proper ventilation in the workspace.

- Maintenance and upkeep of copper laser engraving machines can be intricate and costly.

Precise and detailed engraving

The precision and detail achieved through copper laser engraving set it apart as a superior technique for creating intricate designs on metal surfaces. The focused beam of the laser allows artisans to etch fine lines, delicate patterns, and intricate textures with unparalleled accuracy, resulting in stunningly precise engravings that showcase the artistry and craftsmanship of the creator.

Fast and efficient process

Copper laser engraving offers a significant advantage in its fast and efficient process, allowing for quick and precise etching of designs onto copper surfaces. The speed at which the laser can engrave intricate patterns ensures timely completion of projects without compromising on quality, making it an ideal choice for artisans and designers looking to streamline their workflow while achieving exceptional results.

Versatile customization options

Copper laser engraving offers versatile customization options, allowing artisans to tailor their designs with precision and creativity. From adjusting engraving depths to controlling the intensity of the laser beam, the flexibility of copper laser engraving enables artists to create a wide range of effects, from intricate patterns to bold text. This level of customization empowers designers to bring their unique visions to life on copper surfaces, resulting in truly personalized and distinctive creations that stand out with exceptional detail and sophistication.

Ability to create intricate designs with sharp edges

One of the standout advantages of copper laser engraving is its remarkable ability to create intricate designs with sharp edges. The precision and detail achieved through this process are unparalleled, allowing artisans to etch complex patterns and fine lines onto copper surfaces with exceptional clarity and definition. This level of precision not only enhances the aesthetic appeal of the final product but also showcases the mastery of craftsmanship that can be achieved through the art of copper laser engraving.

High-quality finishes on copper surfaces

Copper laser engraving excels in producing high-quality finishes on copper surfaces, showcasing intricate designs with sharp edges and smooth textures. The precision of the laser beam allows for detailed etching that enhances the overall aesthetic appeal of the copper material. This pro of copper laser engraving ensures that every project, whether it be custom jewelry, decorative art pieces, or personalized gifts, is elevated to a level of sophistication and elegance that captivates the eye and adds a touch of luxury to any creation.

Initial setup costs for copper laser engraving equipment can be high.

The primary drawback of copper laser engraving lies in the significant initial setup costs associated with acquiring the necessary equipment. Investing in copper laser engraving machines can be a substantial financial commitment, especially for small businesses or individual artisans. The high upfront expenses for purchasing and installing the specialized machinery may pose a barrier to entry for those looking to venture into copper engraving. Despite the long-term benefits and efficiency of laser technology, the initial capital outlay required for setting up a copper laser engraving operation can be a challenging aspect to navigate for businesses seeking to adopt this advanced engraving technique.

Copper is a highly reflective material, which may require specialized techniques to optimize engraving quality.

Due to its high reflectivity, copper presents a challenge in laser engraving as the intense laser beam can bounce off the surface, potentially leading to inconsistent engraving depth and quality. Specialized techniques and equipment are often required to effectively manage this reflective nature of copper and optimize the engraving process. Without proper adjustments, the reflective properties of copper can hinder the precision and clarity of engraved designs, necessitating careful consideration and expertise to achieve desired results in copper laser engraving projects.

Laser engraving on copper can produce heat-affected zones that may affect the appearance of the final design.

Laser engraving on copper can present a significant challenge due to the creation of heat-affected zones during the process. These zones, caused by the intense heat generated by the laser beam, can alter the appearance of the final design, leading to discoloration or distortion in the engraved area. The presence of heat-affected zones poses a risk of compromising the overall quality and aesthetic appeal of the copper engraving, requiring careful consideration and precise control of laser parameters to minimize these unwanted effects and achieve desired results.

Complex designs with fine details may take longer to engrave on copper, increasing production time and cost.

Complex designs with fine details may present a challenge in copper laser engraving due to the intricate nature of the patterns. The precision required to etch delicate elements can result in longer engraving times, ultimately extending production schedules and increasing costs. As each intricate detail demands meticulous attention from the laser, the process of engraving complex designs on copper may require additional time and resources to ensure the desired level of accuracy and quality. This con highlights the trade-off between intricacy and efficiency in copper laser engraving, emphasizing the importance of balancing design complexity with production considerations.

Copper laser engraving may emit fumes or odors during the process, requiring proper ventilation in the workspace.

During copper laser engraving, a notable con is the potential emission of fumes or odors as a byproduct of the process. These emissions can pose health risks and unpleasant working conditions if not properly managed. Adequate ventilation in the workspace is essential to ensure the safety of individuals operating the equipment and to maintain air quality. Implementing proper ventilation systems is crucial to mitigate the impact of fumes and odors, safeguarding both the environment and the well-being of those involved in copper laser engraving projects.

Maintenance and upkeep of copper laser engraving machines can be intricate and costly.

Maintenance and upkeep of copper laser engraving machines can pose a significant challenge due to their intricate components and specialized technology. The complexity of these machines often requires skilled technicians and specific tools for maintenance tasks, leading to increased costs in terms of both labor and resources. Regular servicing and calibration are essential to ensure the machine operates at peak performance, adding to the overall maintenance expenses. Additionally, any unexpected breakdowns or malfunctions may result in costly repairs and downtime, impacting productivity and efficiency in the long run. Managing the maintenance needs of copper laser engraving machines demands careful attention and investment to sustain their functionality and longevity effectively.

No Responses