The Power of CO2 Laser in Metal Processing

CO2 lasers have revolutionized the metal processing industry with their exceptional precision and versatility. These high-powered lasers use a carbon dioxide gas mixture to generate a laser beam that is ideal for cutting, engraving, welding, and marking various types of metals.

One of the key advantages of CO2 lasers in metal processing is their ability to deliver clean and precise cuts with minimal heat-affected zones. This results in high-quality finishes and reduces the need for additional finishing processes. Additionally, CO2 lasers are highly efficient and can significantly increase productivity in metal fabrication operations.

CO2 lasers are particularly well-suited for cutting thin to medium-thickness metals such as stainless steel, aluminum, and carbon steel. Their ability to cut intricate shapes with tight tolerances makes them indispensable tools in industries such as automotive, aerospace, electronics, and jewelry manufacturing.

Another benefit of CO2 lasers is their versatility in marking and engraving metals. Whether it’s adding serial numbers, logos, or decorative patterns, CO2 lasers can create precise and permanent marks on a variety of metal surfaces without compromising the material’s integrity.

When it comes to welding applications, CO2 lasers offer fast processing speeds and excellent control over the welding parameters. This results in strong and consistent welds that meet the stringent quality requirements of industries such as automotive assembly, medical device manufacturing, and precision engineering.

In conclusion, CO2 lasers have proven to be indispensable tools in metal processing due to their precision, efficiency, and versatility. As technology continues to advance, we can expect further innovations that will enhance the capabilities of CO2 lasers and drive new possibilities in the world of metal fabrication.

Understanding CO2 Laser Capabilities: Engraving and Cutting Metal

- Can you use a CO2 laser on metal?

- Can 80w CO2 laser engrave metal?

- How does a CO2 laser cut metal?

- Can a 100w CO2 laser cut metal?

Can you use a CO2 laser on metal?

One of the most frequently asked questions regarding CO2 lasers is whether they can be used on metal. The answer is yes, CO2 lasers are highly effective tools for cutting, engraving, welding, and marking various types of metals. With their exceptional precision and versatility, CO2 lasers have become indispensable in the metal processing industry. Whether you need to cut intricate shapes in stainless steel, engrave logos on aluminum, or weld components in carbon steel, a CO2 laser can deliver clean and precise results with minimal heat-affected zones. The ability to work with a wide range of metals makes CO2 lasers a popular choice for industries such as automotive, aerospace, electronics, and jewelry manufacturing.

Can 80w CO2 laser engrave metal?

The question of whether an 80W CO2 laser can engrave metal is a common one in the laser engraving community. While CO2 lasers are primarily designed for cutting and engraving non-metallic materials such as wood, acrylic, and leather, they are not typically suitable for directly engraving metal surfaces. The wavelength of CO2 lasers is not well-absorbed by most metals, making it challenging to achieve the desired results. However, there are specialized techniques such as using marking compounds or coatings that can enable limited metal engraving with a CO2 laser, but for optimal results on metal surfaces, other types of lasers like fiber lasers are more commonly recommended due to their specific capabilities for metal marking and engraving.

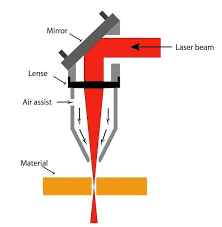

How does a CO2 laser cut metal?

A CO2 laser cuts metal by focusing a high-powered laser beam generated from a carbon dioxide gas mixture onto the metal surface. The intense heat from the laser beam rapidly melts and vaporizes the metal, creating a narrow kerf with minimal heat-affected zones. This process, known as thermal cutting, allows the CO2 laser to precisely cut through various types of metals with exceptional speed and accuracy. Additionally, the assist gas, typically oxygen or nitrogen, helps to blow away molten metal and debris, resulting in clean and smooth cuts. The ability of CO2 lasers to deliver precise cuts without physical contact makes them ideal for cutting intricate shapes and patterns in thin to medium-thickness metals across a wide range of industrial applications.

Can a 100w CO2 laser cut metal?

The question of whether a 100W CO2 laser can cut metal is a common one in the laser processing industry. While a 100W CO2 laser is typically not powerful enough to cut through thick or dense metals, it can be effective for cutting thin metals such as stainless steel, aluminum, and carbon steel. The key factors that determine the cutting capabilities of a CO2 laser include the type of metal being processed, its thickness, and the specific parameters of the laser system. It’s important to consult with experts in laser technology to determine the most suitable laser power and settings for your specific metal cutting needs.

No Responses