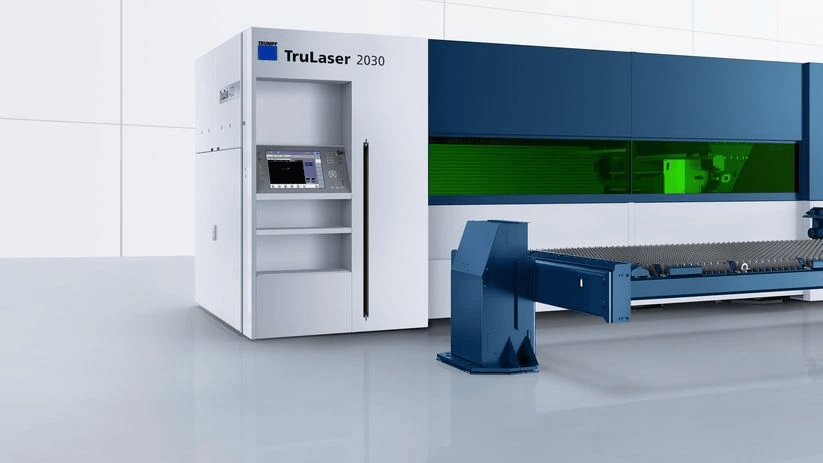

The Best Laser Cutting Machine for Precision and Efficiency

When it comes to precision cutting in various industries, a high-quality laser cutting machine can make all the difference. With advancements in technology, laser cutting machines have become essential tools for achieving accuracy, speed, and efficiency in cutting a wide range of materials.

So, what makes the best laser cutting machine stand out from the rest? Here are some key features to consider:

Cutting Speed and Accuracy

The best laser cutting machines offer high cutting speeds without compromising on accuracy. Look for a machine that can handle intricate designs with precision while completing projects in a timely manner.

Power and Versatility

A versatile laser cutting machine with adjustable power settings allows you to work with different materials of varying thicknesses. Whether you’re cutting metal, wood, acrylic, or other materials, a powerful machine gives you the flexibility to tackle diverse projects.

Ease of Use and Maintenance

An intuitive user interface and easy-to-use software are essential for maximizing productivity. The best laser cutting machines come with user-friendly controls that simplify operation and maintenance tasks, ensuring smooth workflow and minimal downtime.

Safety Features

Safety should always be a top priority when working with laser technology. Look for a machine equipped with safety features such as emergency stop buttons, protective enclosures, and automatic shut-off mechanisms to protect operators from potential hazards.

Durability and Reliability

Investing in a durable and reliable laser cutting machine ensures long-term performance and minimal maintenance costs. Choose a machine from a reputable manufacturer known for producing high-quality equipment that stands the test of time.

Whether you’re in the manufacturing industry, signage business, or creative arts field, having the best laser cutting machine at your disposal can elevate your projects to new heights of precision and efficiency. With the right machine by your side, you can unlock endless possibilities for creating intricate designs with unmatched accuracy.

7 Essential Tips for Choosing the Best Laser Cutting Machine

- Choose a laser cutting machine with the appropriate power level for your intended applications.

- Consider the bed size of the laser cutting machine to ensure it can accommodate your materials.

- Look for a machine with user-friendly software for easier operation and design customization.

- Check the cutting speed and precision of the laser machine to meet your production needs.

- Ensure proper ventilation and safety features are in place when using a laser cutting machine.

- Regularly maintain and clean your laser cutter to prolong its lifespan and maintain cutting quality.

- Invest in training for operators to maximize efficiency and safety when using the laser cutting machine.

Choose a laser cutting machine with the appropriate power level for your intended applications.

When selecting the best laser cutting machine for your needs, it is crucial to consider the power level that aligns with your intended applications. Choosing a laser cutting machine with the appropriate power ensures that you can efficiently and effectively cut through materials of varying thicknesses with precision. Whether you are working on intricate designs or industrial projects, matching the power level to your specific applications will guarantee optimal performance and desired results.

Consider the bed size of the laser cutting machine to ensure it can accommodate your materials.

When selecting the best laser cutting machine for your needs, it is crucial to consider the bed size of the machine. The bed size determines the maximum dimensions of materials that can be accommodated for cutting. Ensuring that the laser cutting machine has a bed size large enough to handle your materials is essential for achieving seamless and efficient cutting processes. By carefully evaluating and matching the bed size to your material requirements, you can optimize productivity and minimize material wastage, ultimately enhancing the overall performance of your laser cutting operations.

Look for a machine with user-friendly software for easier operation and design customization.

When searching for the best laser cutting machine, prioritize models that feature user-friendly software to streamline operation and enhance design customization. A machine with intuitive software not only simplifies the cutting process but also empowers users to create intricate designs with ease. By investing in a laser cutting machine with user-friendly software, you can optimize workflow efficiency and unlock the full potential of your projects through seamless operation and customizable design capabilities.

Check the cutting speed and precision of the laser machine to meet your production needs.

When selecting the best laser cutting machine for your needs, it is crucial to assess the cutting speed and precision capabilities of the machine. By evaluating these factors, you can ensure that the laser machine aligns with your production requirements and can deliver the level of efficiency and accuracy necessary for your projects. Choosing a machine that offers optimal cutting speed and precision will not only enhance productivity but also guarantee high-quality results that meet your standards.

Ensure proper ventilation and safety features are in place when using a laser cutting machine.

When utilizing a laser cutting machine, it is crucial to prioritize safety measures by ensuring proper ventilation and the presence of essential safety features. Adequate ventilation helps to remove potentially harmful fumes and particles generated during the cutting process, promoting a safer working environment for operators. Additionally, having safety features such as emergency stop buttons, protective enclosures, and interlock systems in place can prevent accidents and protect individuals from potential hazards associated with laser technology. Prioritizing ventilation and safety features not only ensures a secure working environment but also contributes to efficient and smooth operations when using a laser cutting machine.

Regularly maintain and clean your laser cutter to prolong its lifespan and maintain cutting quality.

Regular maintenance and cleaning of your laser cutter are crucial steps in ensuring its longevity and preserving cutting quality. By routinely maintaining and cleaning your machine, you can prevent dust buildup, debris accumulation, and potential wear and tear on critical components. This proactive approach not only extends the lifespan of your laser cutter but also helps maintain consistent cutting performance over time, allowing you to achieve optimal results with every project.

Invest in training for operators to maximize efficiency and safety when using the laser cutting machine.

Investing in training for operators is crucial to maximizing efficiency and ensuring safety when using the best laser cutting machine. Proper training equips operators with the knowledge and skills needed to operate the machine effectively, resulting in increased productivity and reduced downtime. Additionally, training on safety protocols helps prevent accidents and promotes a secure working environment. By prioritizing operator training, businesses can optimize the performance of their laser cutting machine while safeguarding the well-being of their employees.

No Responses