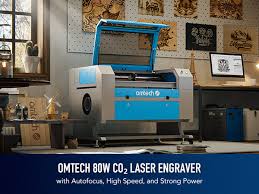

The Power of 80 Watt CO2 Laser: Unleashing Precision and Efficiency

When it comes to laser technology, power and precision are key factors that determine the effectiveness of a laser system. The 80 Watt CO2 laser is a powerhouse in the world of laser cutting and engraving, offering unparalleled performance and versatility.

With its high wattage output, the 80 Watt CO2 laser is capable of cutting through a wide range of materials with ease. From acrylic and wood to metal and glass, this laser system delivers clean and precise cuts, making it ideal for various industries such as manufacturing, signage, and prototyping.

One of the standout features of the 80 Watt CO2 laser is its ability to achieve intricate engraving details on different surfaces. Whether you’re looking to add branding to products or create intricate designs on promotional items, this laser system offers unmatched precision that ensures your projects stand out.

Moreover, the efficiency of the 80 Watt CO2 laser allows for faster turnaround times without compromising on quality. Its high-powered beam ensures swift cutting and engraving processes, making it a valuable asset for businesses looking to increase productivity while maintaining superior results.

Not only does the 80 Watt CO2 laser excel in performance, but it also offers user-friendly features that enhance ease of operation. With intuitive controls and software compatibility, users can easily customize settings and optimize their workflow for maximum efficiency.

In conclusion, the 80 Watt CO2 laser represents a perfect blend of power, precision, and efficiency in the realm of laser technology. Whether you’re a small business looking to elevate your production capabilities or a large-scale manufacturer seeking reliable cutting and engraving solutions, this versatile laser system is sure to meet your needs with exceptional performance.

5 Essential Safety Tips for Operating an 80 Watt CO2 Laser

- Ensure proper ventilation when operating an 80 watt CO2 laser to remove fumes and particles produced during cutting or engraving.

- Always wear appropriate safety gear, such as goggles, when working with an 80 watt CO2 laser to protect your eyes from the laser beam.

- Regularly check and maintain the alignment of the laser beam to ensure optimal cutting and engraving results with an 80 watt CO2 laser.

- Use the correct settings for different materials when using an 80 watt CO2 laser to achieve desired cutting or engraving effects without damaging the material.

- Keep a fire extinguisher nearby when operating an 80 watt CO2 laser to quickly extinguish any potential fires caused by sparks or flammable materials.

Ensure proper ventilation when operating an 80 watt CO2 laser to remove fumes and particles produced during cutting or engraving.

Ensuring proper ventilation is crucial when operating an 80 Watt CO2 laser to effectively remove fumes and particles generated during cutting or engraving processes. Proper ventilation not only helps maintain a clean and safe working environment but also minimizes potential health risks associated with inhaling harmful fumes. By implementing adequate ventilation systems, users can optimize the performance of their laser system while prioritizing the well-being of themselves and others in the vicinity.

Always wear appropriate safety gear, such as goggles, when working with an 80 watt CO2 laser to protect your eyes from the laser beam.

When working with an 80 Watt CO2 laser, it is crucial to prioritize safety by wearing appropriate protective gear, such as goggles. These safety measures are essential to shield your eyes from the powerful laser beam and prevent any potential harm or damage. By ensuring that you have the proper safety equipment in place, you can work confidently and securely with the 80 Watt CO2 laser, minimizing risks and prioritizing your well-being.

Regularly check and maintain the alignment of the laser beam to ensure optimal cutting and engraving results with an 80 watt CO2 laser.

Regularly checking and maintaining the alignment of the laser beam is crucial to achieving optimal cutting and engraving results with an 80 Watt CO2 laser. Proper alignment ensures that the laser beam remains focused and accurate, allowing for precise cuts and detailed engravings on various materials. By staying vigilant in monitoring the alignment of the laser beam, users can maximize the performance of their 80 Watt CO2 laser system, leading to consistent and high-quality output for a wide range of applications.

Use the correct settings for different materials when using an 80 watt CO2 laser to achieve desired cutting or engraving effects without damaging the material.

To maximize the effectiveness of an 80 Watt CO2 laser, it is crucial to use the correct settings tailored to specific materials. By adjusting the laser power, speed, and frequency based on the material being processed, users can achieve desired cutting or engraving effects without risking damage to the material. This attention to detail ensures precision and quality in the results, allowing for smooth and efficient operations while maintaining the integrity of the materials being worked on.

Keep a fire extinguisher nearby when operating an 80 watt CO2 laser to quickly extinguish any potential fires caused by sparks or flammable materials.

It is crucial to prioritize safety when operating an 80 Watt CO2 laser. Keeping a fire extinguisher nearby is essential to swiftly extinguish any potential fires that may arise from sparks or flammable materials during operation. This proactive measure ensures a quick response in case of emergencies, helping to mitigate risks and safeguard both personnel and equipment in the workspace.

No Responses