The Power of Precision: Exploring 3D Glass Engraving Machines

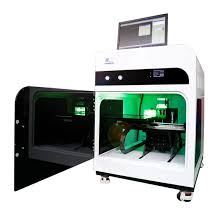

3D glass engraving machines are revolutionizing the art of glass etching and customization. These cutting-edge machines utilize advanced technology to create intricate designs and patterns on glass surfaces with unparalleled precision and detail.

One of the key features of 3D glass engraving machines is their ability to engrave three-dimensional designs onto glass, adding depth and dimension to the artwork. This capability opens up a world of creative possibilities for artists, designers, and manufacturers looking to elevate their glass products to new heights.

Whether you’re creating personalized gifts, custom signage, or decorative glassware, a 3D glass engraving machine offers unmatched versatility and flexibility. With the ability to engrave on various types of glass, including flat surfaces, curved objects, and even cylindrical shapes, these machines provide endless opportunities for creativity.

Furthermore, 3D glass engraving machines are equipped with high-powered lasers that deliver precise and consistent results. This level of accuracy ensures that even the most intricate designs are engraved flawlessly onto the glass surface, resulting in stunning finished products that captivate and impress.

From corporate branding to artistic expression, 3D glass engraving machines are transforming the way we approach glass customization. Their speed, efficiency, and reliability make them indispensable tools for businesses and individuals looking to stand out in a competitive market.

Experience the power of precision with a 3D glass engraving machine and unlock a world of creative possibilities in the realm of glass artistry.

Mastering 3D Glass Engraving: 9 Essential Tips for Precision and Safety

- Ensure the glass surface is clean and free of dust before engraving.

- Use high-quality engraving bits to achieve precise and detailed designs.

- Adjust the engraving speed and power settings according to the type of glass being engraved.

- Regularly calibrate the machine to maintain accuracy in engravings.

- Experiment with different engraving depths to create varying effects on the glass.

- Consider using protective eyewear when operating the machine to prevent eye damage from glass debris.

- Choose appropriate design software that is compatible with your 3D glass engraving machine.

- Practice on scrap pieces of glass before working on final projects to perfect your technique.

- Follow all safety guidelines provided by the manufacturer for safe operation of the machine.

Ensure the glass surface is clean and free of dust before engraving.

To achieve optimal results when using a 3D glass engraving machine, it is crucial to ensure that the glass surface is clean and free of dust before beginning the engraving process. Dust particles or debris on the glass can interfere with the precision of the engraving, leading to imperfect results. By taking the time to thoroughly clean the glass surface beforehand, you can ensure that your designs are etched with clarity and accuracy, resulting in stunning finished products that showcase the full potential of your 3D glass engraving machine.

Use high-quality engraving bits to achieve precise and detailed designs.

To achieve precise and detailed designs with a 3D glass engraving machine, it is essential to use high-quality engraving bits. These specialized tools play a crucial role in determining the clarity and accuracy of the engraved patterns on glass surfaces. By investing in top-notch engraving bits, users can ensure that their designs are executed with finesse and intricacy, resulting in stunning finished products that showcase the full potential of the technology.

Adjust the engraving speed and power settings according to the type of glass being engraved.

When using a 3D glass engraving machine, it is crucial to adjust the engraving speed and power settings based on the type of glass being engraved. Different types of glass have varying hardness and composition, requiring customized settings to achieve optimal results. By fine-tuning the speed and power parameters, users can ensure precise and clean engravings that enhance the overall quality of the finished product. This attention to detail not only improves efficiency but also prolongs the lifespan of the machine and maintains consistent engraving performance over time.

Regularly calibrate the machine to maintain accuracy in engravings.

Regular calibration of your 3D glass engraving machine is essential to ensure the accuracy and precision of your engravings. By regularly calibrating the machine, you can maintain consistent results and avoid any deviations in the quality of your work. Calibration helps to fine-tune the settings of the machine, optimizing its performance and ensuring that each engraving meets your exact specifications. By incorporating regular calibration into your maintenance routine, you can maximize the potential of your 3D glass engraving machine and produce flawless designs with every project.

Experiment with different engraving depths to create varying effects on the glass.

By experimenting with different engraving depths on a 3D glass engraving machine, you can unlock a world of creative possibilities and achieve varying effects on the glass surface. Adjusting the depth of the engraving allows you to create intricate designs with layers of depth, adding texture and dimension to your artwork. Whether you aim for a subtle frosted effect or a bold raised design, playing with engraving depths enables you to tailor the final look to suit your artistic vision.

Consider using protective eyewear when operating the machine to prevent eye damage from glass debris.

When operating a 3D glass engraving machine, it is essential to consider using protective eyewear to safeguard against potential eye damage caused by glass debris. The high precision and power of the machine can generate small glass particles that may pose a risk to the eyes. By wearing protective eyewear, operators can ensure their safety and maintain clear vision while working with the machine, promoting a secure and productive engraving process.

Choose appropriate design software that is compatible with your 3D glass engraving machine.

Selecting the right design software that is compatible with your 3D glass engraving machine is crucial for achieving optimal results. By choosing software that seamlessly integrates with your machine, you can ensure that your designs are accurately translated onto the glass surface with precision and clarity. Compatibility between the software and the engraving machine not only streamlines the design process but also enhances efficiency and accuracy, ultimately leading to superior finished products that meet your exact specifications.

Practice on scrap pieces of glass before working on final projects to perfect your technique.

To enhance your skills and refine your technique when using a 3D glass engraving machine, it is highly recommended to practice on scrap pieces of glass before embarking on your final projects. This approach allows you to familiarize yourself with the machine’s settings, experiment with different designs, and fine-tune your engraving process without the pressure of working on a finished piece. By honing your skills on practice pieces, you can gain confidence and precision, ensuring that your final projects are executed with the highest level of expertise and quality.

Follow all safety guidelines provided by the manufacturer for safe operation of the machine.

It is crucial to follow all safety guidelines provided by the manufacturer for the safe operation of a 3D glass engraving machine. These guidelines are designed to protect both the user and the machine, ensuring that operations are carried out smoothly and without risk. By adhering to these safety protocols, users can minimize the potential for accidents or damage, allowing them to focus on creating intricate and beautiful designs with confidence and peace of mind.

No Responses