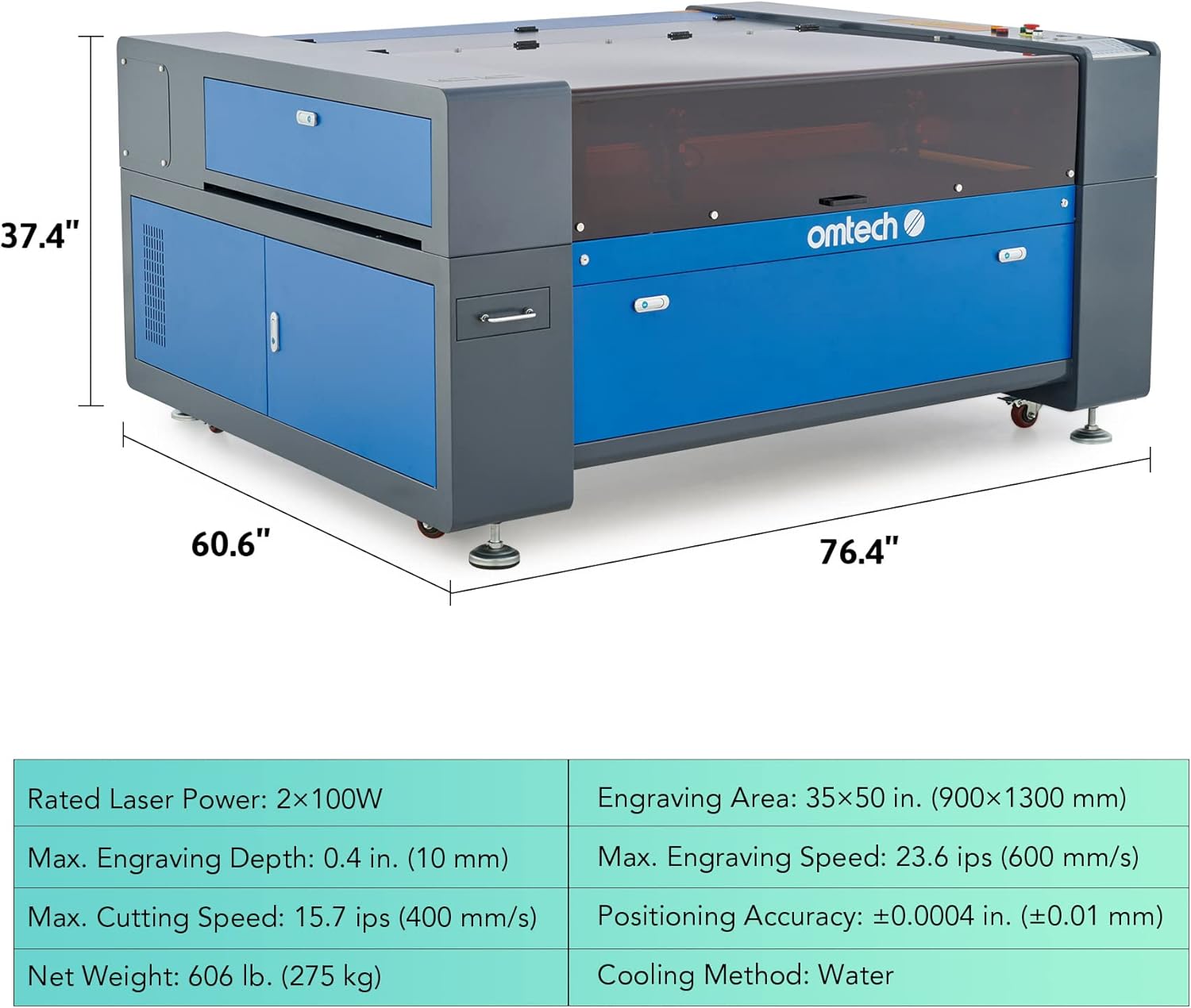

The Power of a 100W Laser Engraver

When it comes to precision and efficiency in laser engraving, a 100W laser engraver stands out as a powerful tool that offers exceptional capabilities. With its high wattage output, this type of engraver is ideal for a wide range of applications across various industries.

One of the key advantages of a 100W laser engraver is its ability to work quickly and accurately on a variety of materials. Whether you’re engraving wood, acrylic, glass, metal, or even stone, the high power output ensures that the engraving process is efficient and produces crisp, detailed results.

Another benefit of a 100W laser engraver is its versatility. From creating intricate designs on jewelry to marking serial numbers on industrial parts, this type of engraver can handle a diverse array of projects with ease. Its high power output allows for deeper cuts and faster processing times, making it an invaluable tool for businesses looking to streamline their production processes.

In addition to its power and versatility, a 100W laser engraver offers precision and repeatability in every project. The focused beam ensures that even the most intricate details are engraved with accuracy, giving your products a professional finish that sets them apart from the competition.

Whether you’re a small business looking to enhance your product offerings or a large manufacturer seeking to improve efficiency in your production line, investing in a 100W laser engraver can be a game-changer. Its combination of power, speed, and precision makes it an indispensable tool for anyone looking to take their engraving capabilities to the next level.

Discover the possibilities with a 100W laser engraver and unlock new opportunities for creativity and innovation in your projects.

6 Essential Safety and Maintenance Tips for Using a 100W Laser Engraver

- Always wear appropriate safety gear, such as goggles, when operating the 100W laser engraver.

- Ensure proper ventilation in the workspace to prevent inhaling fumes or particles produced during engraving.

- Regularly clean the lens of the laser engraver to maintain optimal performance and clarity in engravings.

- Calibrate the focus of the laser beam for different materials to achieve precise and consistent results.

- Avoid leaving the 100W laser engraver unattended while it is in operation to prevent accidents or damage.

- Refer to the manufacturer’s guidelines and user manual for maintenance procedures and troubleshooting tips.

Always wear appropriate safety gear, such as goggles, when operating the 100W laser engraver.

When using a 100W laser engraver, it is crucial to prioritize safety by wearing the necessary protective gear, such as goggles. The high power output of the laser can pose potential risks to the eyes, making it essential to shield them from any harmful exposure. By always wearing appropriate safety gear like goggles, operators can ensure their well-being and maintain a safe working environment while operating the 100W laser engraver.

Ensure proper ventilation in the workspace to prevent inhaling fumes or particles produced during engraving.

It is crucial to prioritize proper ventilation in the workspace when using a 100W laser engraver to prevent inhaling fumes or particles generated during the engraving process. Adequate ventilation not only ensures a healthier work environment but also reduces the risk of respiratory issues associated with exposure to potentially harmful substances. By maintaining good airflow and implementing effective ventilation measures, users can safeguard their well-being while maximizing the efficiency and safety of their laser engraving operations.

Regularly clean the lens of the laser engraver to maintain optimal performance and clarity in engravings.

Regularly cleaning the lens of your 100W laser engraver is essential for maintaining optimal performance and clarity in your engravings. Dust, debris, and residue can accumulate on the lens over time, affecting the quality of your engravings. By keeping the lens clean and free from any obstructions, you ensure that the laser beam remains focused and precise, resulting in crisp and detailed engravings every time. Make it a habit to include lens cleaning as part of your regular maintenance routine to maximize the efficiency and longevity of your 100W laser engraver.

Calibrate the focus of the laser beam for different materials to achieve precise and consistent results.

To optimize the performance of your 100W laser engraver, it is crucial to calibrate the focus of the laser beam according to the specific material you are working with. By adjusting the focus for different materials, you can achieve precise and consistent results in your engraving projects. This attention to detail ensures that the laser beam interacts with the material effectively, resulting in sharp and accurate engravings every time. Calibration not only enhances the quality of your work but also maximizes the efficiency of your engraving process, making it a key step in achieving exceptional outcomes with your 100W laser engraver.

Avoid leaving the 100W laser engraver unattended while it is in operation to prevent accidents or damage.

It is crucial to avoid leaving the 100W laser engraver unattended during operation to mitigate the risk of accidents or potential damage. By staying vigilant and monitoring the engraving process closely, you can ensure the safety of both the equipment and surrounding environment. Taking proactive measures to oversee the operation of the laser engraver helps maintain a secure working environment and prevents any unforeseen incidents that may arise from neglecting supervision.

Refer to the manufacturer’s guidelines and user manual for maintenance procedures and troubleshooting tips.

When utilizing a 100W laser engraver, it is crucial to refer to the manufacturer’s guidelines and user manual for maintenance procedures and troubleshooting tips. Following these recommendations ensures that the engraver operates efficiently and effectively over time. Regular maintenance, as outlined by the manufacturer, can help prevent issues and prolong the lifespan of the equipment. In case of any technical difficulties or performance issues, consulting the user manual for troubleshooting guidance can aid in identifying and resolving problems promptly, minimizing downtime and optimizing productivity.

No Responses