Exploring the World of Entry-Level Fiber Lasers

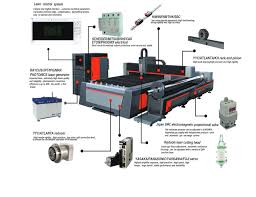

When it comes to laser technology, fiber lasers have revolutionized various industries with their efficiency and precision. While fiber lasers are known for their high performance and reliability, entry-level fiber lasers offer a cost-effective solution for businesses looking to enter the world of laser cutting and engraving.

Entry-level fiber lasers are designed for small to medium-sized businesses or hobbyists who require a reliable and affordable laser system. These compact machines are easy to operate and maintain, making them ideal for beginners or those with limited experience in using laser technology.

Despite being entry-level, these fiber lasers boast impressive cutting and engraving capabilities. With high-speed processing and exceptional accuracy, they can handle a wide range of materials, including metals, plastics, wood, and more. This versatility makes them suitable for various applications, from signage and jewelry making to industrial prototyping.

One of the key advantages of entry-level fiber lasers is their energy efficiency. Compared to traditional CO2 lasers, fiber lasers consume less power while delivering superior performance. This not only reduces operating costs but also minimizes environmental impact, making them a sustainable choice for businesses conscious of their carbon footprint.

Furthermore, entry-level fiber lasers often come equipped with user-friendly software that simplifies the design and cutting process. This intuitive interface allows users to create intricate designs with ease and precision, ensuring high-quality results every time.

In conclusion, entry-level fiber lasers offer an accessible entry point into the world of laser technology without compromising on quality or performance. Whether you’re starting a new business or expanding your existing capabilities, these compact yet powerful machines provide a reliable solution for all your cutting and engraving needs.

Essential Safety and Maintenance Tips for Entry-Level Fiber Laser Operators

- Ensure proper ventilation in the working area to prevent fumes and smoke buildup.

- Always wear appropriate personal protective equipment, such as safety glasses, when operating the fiber laser.

- Regularly clean the lens of the fiber laser to maintain optimal cutting and engraving quality.

- Follow manufacturer’s guidelines for power settings and material compatibility to avoid damage to the machine or materials.

- Calibrate the focus of the laser beam regularly for precise and accurate cutting/engraving results.

- Keep a fire extinguisher nearby as a precautionary measure in case of any unexpected flare-ups during operation.

- Attend training sessions or seek guidance from experienced users to improve your skills and maximize efficiency.

Ensure proper ventilation in the working area to prevent fumes and smoke buildup.

To maximize the efficiency and safety of your entry-level fiber laser, it is crucial to ensure proper ventilation in the working area. By preventing fumes and smoke buildup, you not only maintain a clean and healthy environment but also protect the integrity of your machine and the quality of your work. Adequate ventilation helps to dissipate potentially harmful emissions, ensuring smooth operation and optimal performance of your fiber laser system.

Always wear appropriate personal protective equipment, such as safety glasses, when operating the fiber laser.

When operating an entry-level fiber laser, it is crucial to prioritize safety by wearing appropriate personal protective equipment, such as safety glasses. These safety measures are essential to protect your eyes from potential laser radiation and debris that may be generated during the cutting or engraving process. By wearing safety glasses, you ensure a safe working environment and reduce the risk of eye injuries, allowing you to operate the fiber laser with confidence and peace of mind.

Regularly clean the lens of the fiber laser to maintain optimal cutting and engraving quality.

Regularly cleaning the lens of your entry-level fiber laser is essential to ensure optimal cutting and engraving quality. Dust, debris, and residue can accumulate on the lens over time, affecting the laser beam’s focus and accuracy. By maintaining a clean lens, you can maximize the performance of your fiber laser system, resulting in crisp and precise cuts or engravings on a variety of materials. Incorporating this simple maintenance tip into your routine will help prolong the lifespan of your machine and ensure consistent high-quality output for all your projects.

Follow manufacturer’s guidelines for power settings and material compatibility to avoid damage to the machine or materials.

It is crucial to adhere to the manufacturer’s guidelines for power settings and material compatibility when using an entry-level fiber laser. By following these recommendations, you can prevent potential damage to the machine and ensure optimal performance. Incorrect power settings may not only affect the quality of your cuts or engravings but can also lead to safety hazards. Additionally, using incompatible materials can result in damage to both the machine and the materials being processed. Therefore, it is essential to carefully follow the manufacturer’s instructions to maximize the efficiency and longevity of your entry-level fiber laser system.

Calibrate the focus of the laser beam regularly for precise and accurate cutting/engraving results.

To achieve precise and accurate cutting or engraving results with an entry-level fiber laser, it is essential to calibrate the focus of the laser beam regularly. Proper calibration ensures that the laser beam is concentrated at the optimal focal point, maximizing its cutting or engraving efficiency. By maintaining a sharp focus, users can achieve finer details and cleaner cuts on a variety of materials, enhancing the overall quality of their work. Regular calibration of the laser beam’s focus is key to achieving consistent and professional results with an entry-level fiber laser system.

Keep a fire extinguisher nearby as a precautionary measure in case of any unexpected flare-ups during operation.

As a precautionary measure during the operation of entry-level fiber lasers, it is highly recommended to keep a fire extinguisher nearby. This safety tip ensures that you are prepared in the event of any unexpected flare-ups that may occur during laser cutting or engraving processes. Having a fire extinguisher within reach not only helps to mitigate potential risks but also promotes a safe working environment, allowing you to handle any emergencies swiftly and effectively.

Attend training sessions or seek guidance from experienced users to improve your skills and maximize efficiency.

To enhance your proficiency and optimize the performance of your entry-level fiber laser, consider attending training sessions or consulting with experienced users. By learning from seasoned professionals in the field, you can gain valuable insights, tips, and techniques that will help you master the operation of your laser system. Seeking guidance from experts can not only improve your skills but also increase efficiency in your laser cutting and engraving processes, ensuring that you achieve the best results possible.

No Responses