The Ultimate Guide to CNC Engraving Bits

CNC engraving has revolutionized the way intricate designs are etched onto various materials. One crucial component of this process is the CNC engraving bit, also known as a router bit or end mill. These bits come in a variety of shapes, sizes, and materials, each serving a specific purpose in achieving precision and detail in your engravings.

Types of CNC Engraving Bits

There are several types of CNC engraving bits available, including:

- Straight Bits: Ideal for simple straight-line engravings.

- Ballnose Bits: Perfect for 3D contouring and creating smooth curves.

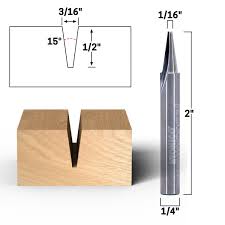

- V-Bits: Used for intricate detail work and sharp angles.

- Engraving Bits: Designed specifically for fine line engraving and text.

Choosing the Right Bit for Your Project

When selecting a CNC engraving bit for your project, consider the following factors:

- Material: Choose a bit that is suitable for the material you are engraving, such as wood, plastic, metal, or glass.

- Detail Level: Select a bit that matches the level of detail you want to achieve in your design.

- Speed and Feed Rates: Adjust the cutting speed and feed rates based on the bit’s specifications to optimize performance.

Maintaining Your CNC Engraving Bits

To ensure optimal performance and longevity of your CNC engraving bits, follow these maintenance tips:

- Clean the bits regularly to remove debris and buildup that can affect cutting precision.

- Store bits in a dry and secure place to prevent damage or corrosion.

- Replace worn-out bits promptly to maintain consistent engraving quality.

Conclusion

CNC engraving bits are essential tools for achieving intricate designs with precision and accuracy. By understanding the different types of bits available, choosing the right one for your project, and properly maintaining them, you can elevate your engraving capabilities to new heights. Explore the world of CNC engraving bits today and unleash your creativity!

Everything You Need to Know About CNC Engraving Bits: FAQs and Expert Tips

- What are CNC engraving bits?

- What types of materials can CNC engraving bits be used on?

- How do I choose the right CNC engraving bit for my project?

- What is the difference between straight bits and ballnose bits?

- Can CNC engraving bits be re-sharpened or reconditioned?

- What factors affect the lifespan of CNC engraving bits?

- Are there specific speed and feed rates I should follow when using CNC engraving bits?

- How should I store and maintain my CNC engraving bits?

- Where can I purchase high-quality CNC engraving bits?

What are CNC engraving bits?

CNC engraving bits are specialized cutting tools designed for use with computer numerical control (CNC) machines to create detailed engravings on various materials. These bits come in a variety of shapes and sizes, each tailored to specific engraving tasks, such as straight-line engraving, 3D contouring, fine detail work, and text engraving. CNC engraving bits play a crucial role in achieving precision and intricacy in designs, making them essential tools for artists, craftsmen, and manufacturers looking to add personalized touches or intricate patterns to their projects.

What types of materials can CNC engraving bits be used on?

CNC engraving bits are versatile tools that can be used on a wide range of materials, making them essential for various engraving projects. These bits are suitable for engraving on materials such as wood, plastic, metal, glass, and even certain types of stone. The key to achieving optimal results lies in selecting the right type of bit that matches the material’s properties and adjusting cutting parameters accordingly. Whether you’re working on intricate designs in wood or adding detailed engravings to metal surfaces, CNC engraving bits offer the precision and flexibility needed to bring your creative vision to life across a diverse array of materials.

How do I choose the right CNC engraving bit for my project?

When faced with the question of how to choose the right CNC engraving bit for a project, it’s essential to consider several key factors. Firstly, assess the material you will be working with, as different bits are designed for specific materials such as wood, plastic, metal, or glass. Secondly, evaluate the level of detail required in your design and select a bit that can achieve the desired precision. Additionally, adjusting cutting speed and feed rates based on the bit’s specifications can optimize performance. By carefully considering these factors and matching them to the requirements of your project, you can ensure that you choose the right CNC engraving bit to achieve exceptional results.

What is the difference between straight bits and ballnose bits?

When comparing straight bits and ballnose bits in CNC engraving, the key difference lies in their cutting profiles and applications. Straight bits have a flat cutting edge and are best suited for creating simple straight-line engravings with sharp corners. On the other hand, ballnose bits feature a rounded tip that allows for smooth contouring and the creation of curved surfaces, making them ideal for 3D engraving and intricate designs requiring softer transitions between shapes. Choosing between straight bits and ballnose bits depends on the desired outcome of the engraving project, with each type offering unique advantages in achieving specific design elements and levels of detail.

Can CNC engraving bits be re-sharpened or reconditioned?

One frequently asked question regarding CNC engraving bits is whether they can be re-sharpened or reconditioned. The answer to this question depends on the type of bit and its condition. While some CNC engraving bits, especially those made of high-speed steel or carbide, can be re-sharpened by professionals to restore their cutting edges and extend their lifespan, other types of bits may not be suitable for reconditioning due to their design or material composition. It is recommended to consult with a knowledgeable technician or supplier to determine the feasibility of re-sharpening or reconditioning your specific CNC engraving bit for optimal performance and cost-effectiveness.

What factors affect the lifespan of CNC engraving bits?

The lifespan of CNC engraving bits is influenced by several key factors. One significant factor is the material being engraved, as harder materials like metal can cause more wear on the bits compared to softer materials like wood or plastic. The cutting speed and feed rates used during the engraving process also play a crucial role in determining the longevity of the bits, as excessive speeds or feeds can lead to premature wear and breakage. Proper maintenance, including regular cleaning and storage in a dry environment, is essential for prolonging the lifespan of CNC engraving bits. Additionally, selecting the appropriate bit type and size for the specific engraving task at hand can help optimize performance and durability over time.

Are there specific speed and feed rates I should follow when using CNC engraving bits?

When using CNC engraving bits, one frequently asked question revolves around specific speed and feed rates. The optimal speed and feed rates for CNC engraving bits depend on various factors, including the type of material being engraved, the type and size of the bit, and the desired level of detail in the design. It is crucial to refer to the manufacturer’s recommendations for each specific bit and material combination to ensure precise cutting and efficient operation. Adjusting the speed and feed rates based on these guidelines can help achieve optimal results and prolong the lifespan of both the CNC engraving bits and the machine itself.

How should I store and maintain my CNC engraving bits?

Proper storage and maintenance of CNC engraving bits are crucial to ensure their longevity and optimal performance. To store your CNC engraving bits effectively, it is recommended to keep them in a dry and secure place to prevent any damage or corrosion. Regularly cleaning the bits to remove debris and buildup is essential in maintaining cutting precision. Additionally, promptly replacing worn-out bits is necessary to uphold consistent engraving quality. By following these storage and maintenance practices, you can prolong the lifespan of your CNC engraving bits and achieve superior results in your engraving projects.

Where can I purchase high-quality CNC engraving bits?

When it comes to purchasing high-quality CNC engraving bits, there are several reputable sources to consider. Many specialized online retailers and manufacturers offer a wide selection of premium CNC engraving bits tailored to various materials and applications. Additionally, local distributors and stores specializing in machining tools may also carry a range of top-notch engraving bits. It’s essential to research customer reviews, compare prices, and inquire about the specific features of the bits before making a purchase to ensure you are getting the best quality for your engraving needs.

No Responses