The Power of Laser Technologies

Laser technologies have revolutionized numerous industries and applications, offering precision, efficiency, and versatility like never before. From cutting-edge medical procedures to high-speed manufacturing processes, lasers have become indispensable tools in our modern world.

Medical Advancements

In the field of medicine, lasers are used for a wide range of applications, including surgery, dermatology, ophthalmology, and more. Laser technology enables minimally invasive procedures with pinpoint accuracy, reducing recovery times and improving patient outcomes.

Industrial Applications

In industrial settings, lasers are utilized for cutting, welding, marking, and engraving various materials such as metal, plastic, and wood. The precision and speed of laser processing make it an ideal choice for mass production and customization across industries.

Communication and Information Technology

Laser technologies play a crucial role in communication systems such as fiber optics, enabling high-speed data transmission over long distances. Additionally, lasers are used in optical storage devices like DVDs and Blu-ray discs for data recording and retrieval.

Research and Scientific Discoveries

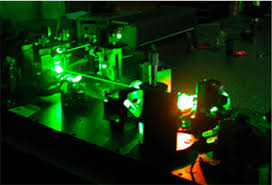

In research laboratories, lasers are instrumental in conducting experiments that require precise measurements or controlled energy delivery. Laser spectroscopy techniques help scientists analyze molecular structures and study chemical reactions at the atomic level.

Entertainment and Artistic Expression

From dazzling light shows to intricate laser art installations, the entertainment industry harnesses the visual impact of lasers to create immersive experiences for audiences worldwide. Laser displays are a popular choice for concerts, events, and multimedia productions.

Looking Ahead

As laser technologies continue to evolve and advance, we can expect even greater innovations in various fields. From quantum computing to space exploration, lasers will undoubtedly play a pivotal role in shaping the future of technology and science.

Embrace the power of laser technologies and explore the endless possibilities they offer in transforming our world!

9 Essential Safety Tips for Using Laser Technology Effectively and Responsibly

- Always wear appropriate eye protection when working with lasers.

- Ensure proper ventilation in the area where lasers are used to prevent accumulation of fumes or vapors.

- Follow manufacturer’s guidelines for maintenance and calibration of laser equipment.

- Be cautious when handling high-powered lasers to avoid accidental exposure.

- Keep laser beams away from flammable materials to prevent fire hazards.

- Never point a laser beam towards people or animals as it can cause harm.

- Understand the different classes of lasers and their safety requirements.

- Regularly inspect optical components for damage or contamination that may affect performance.

- Train personnel on safe practices and emergency procedures related to laser use.

Always wear appropriate eye protection when working with lasers.

When working with lasers, it is crucial to prioritize safety by always wearing appropriate eye protection. Laser beams can cause serious eye damage or even blindness if proper precautions are not taken. By wearing the recommended eye protection, you can safeguard your vision and prevent potential injuries, ensuring a safe and productive work environment when utilizing laser technologies.

Ensure proper ventilation in the area where lasers are used to prevent accumulation of fumes or vapors.

It is crucial to maintain proper ventilation in the workspace where lasers are utilized to prevent the buildup of fumes or vapors. Adequate ventilation not only ensures a safe environment for operators but also helps maintain the efficiency and performance of laser systems. By effectively managing air quality and circulation, potential health hazards associated with laser emissions can be minimized, promoting a healthier and more productive working environment for all individuals involved in laser operations.

Follow manufacturer’s guidelines for maintenance and calibration of laser equipment.

To ensure optimal performance and safety when using laser equipment, it is crucial to adhere to the manufacturer’s guidelines for maintenance and calibration. Regular maintenance and proper calibration help maintain the accuracy and efficiency of the laser system, prolong its lifespan, and minimize the risk of malfunctions or accidents. By following the manufacturer’s recommendations, users can maximize the reliability and longevity of their laser equipment, ensuring consistent results and safe operation in various applications.

Be cautious when handling high-powered lasers to avoid accidental exposure.

When dealing with high-powered lasers, it is crucial to exercise caution to prevent accidental exposure. High-powered lasers can pose serious risks to eye safety and skin health if not handled properly. Always wear appropriate protective gear, such as laser safety goggles, and ensure that the laser beam is directed away from people and reflective surfaces. By following strict safety protocols and being mindful of potential hazards, you can minimize the risk of accidents and ensure a safe working environment when working with high-powered lasers.

Keep laser beams away from flammable materials to prevent fire hazards.

It is crucial to maintain a safe distance between laser beams and flammable materials to mitigate the risk of fire hazards. The intense heat generated by lasers can easily ignite combustible substances, posing a significant danger to both property and personnel. By implementing strict safety protocols and ensuring proper containment measures are in place, the potential for accidents can be minimized, safeguarding against the catastrophic consequences of fires caused by laser interactions with flammable materials.

Never point a laser beam towards people or animals as it can cause harm.

It is crucial to always exercise caution and responsibility when handling laser devices. Pointing a laser beam towards people or animals can pose serious risks and potential harm. The concentrated light emitted by lasers can cause eye injuries, skin burns, and other adverse effects if not used properly. It is essential to prioritize safety measures and ensure that laser beams are directed only at intended targets to prevent accidents and protect the well-being of individuals and animals in the vicinity.

Understand the different classes of lasers and their safety requirements.

It is essential to understand the various classes of lasers and their corresponding safety requirements when working with laser technologies. Laser classification systems categorize lasers based on their potential hazards, such as eye or skin damage, and outline specific safety measures that must be followed to minimize risks. By familiarizing yourself with the safety protocols associated with each laser class, you can ensure a safe working environment and protect yourself and others from potential harm.

Regularly inspect optical components for damage or contamination that may affect performance.

Regularly inspecting optical components for damage or contamination is crucial to maintaining the optimal performance of laser technologies. Even minor issues such as scratches, dust, or debris can significantly impact the efficiency and accuracy of laser systems. By conducting routine inspections and promptly addressing any issues, users can ensure that their optical components remain in top condition, allowing for consistent and reliable operation of their laser equipment.

Train personnel on safe practices and emergency procedures related to laser use.

It is crucial to train personnel on safe practices and emergency procedures associated with laser use to ensure a secure working environment. Proper training not only minimizes the risk of accidents and injuries but also empowers employees to respond effectively in case of any unforeseen incidents. By educating staff on the correct handling of lasers, maintenance protocols, and emergency protocols, organizations can maintain a culture of safety and compliance while maximizing the benefits of laser technologies in various applications.

No Responses