The Power of Glass Laser Engraving Machines

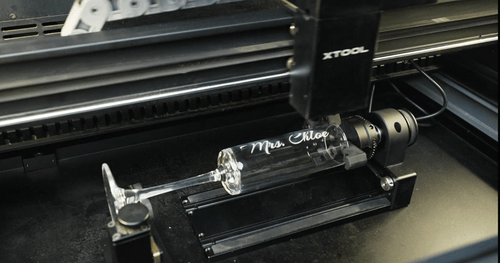

Glass laser engraving machines have revolutionized the way intricate designs and patterns are etched onto glass surfaces. These cutting-edge machines utilize high-powered lasers to create precise and detailed engravings on various types of glass, from delicate glassware to sturdy windows and mirrors.

One of the key advantages of using a glass laser engraving machine is the level of precision it offers. Unlike traditional engraving methods that may result in uneven or inconsistent designs, laser technology ensures that every detail is accurately reproduced with sharp clarity.

Another benefit of glass laser engraving machines is their versatility. Whether you’re looking to personalize a gift with a special message, create custom signage for your business, or add decorative elements to architectural features, these machines can handle a wide range of applications with ease.

Furthermore, glass laser engraving machines are incredibly efficient and time-saving. With the ability to work quickly and accurately, these machines streamline the engraving process, allowing for faster turnaround times without compromising on quality.

Additionally, the non-contact nature of laser engraving minimizes the risk of damage to the glass surface, ensuring a smooth and flawless finish every time. This makes glass laser engraving machines ideal for working with delicate or valuable pieces that require extra care during the engraving process.

In conclusion, glass laser engraving machines represent a powerful tool for achieving intricate and professional-looking engravings on glass surfaces. With their precision, versatility, efficiency, and gentle touch, these machines open up a world of creative possibilities for artists, designers, businesses, and hobbyists alike.

Top 5 Advantages of Using a Glass Laser Engraving Machine for Precision and Quality

- High precision engraving for intricate designs

- Versatile application on various types of glass

- Efficient and time-saving engraving process

- Non-contact technology minimizes risk of damage to glass surfaces

- Professional-looking results with sharp clarity

Considerations Before Investing in a Glass Laser Engraving Machine: Costs, Limitations, and Material Suitability

- High initial cost of purchasing a glass laser engraving machine.

- Maintenance and repair costs can be expensive over time.

- Limited depth of engraving compared to other methods like sandblasting.

- Certain types of glass may not be suitable for laser engraving, limiting material options.

High precision engraving for intricate designs

Glass laser engraving machines offer a remarkable advantage in providing high precision engraving for intricate designs. With the use of advanced laser technology, these machines can achieve unparalleled levels of detail and accuracy, allowing for the reproduction of complex and delicate patterns with sharp clarity. This capability makes glass laser engraving machines a perfect choice for projects that require fine details and intricate designs to be etched onto glass surfaces with precision and finesse.

Versatile application on various types of glass

Glass laser engraving machines offer a remarkable pro in their versatile application on various types of glass. Whether it’s delicate glassware, sturdy windows, decorative mirrors, or architectural features, these machines excel at creating precise and detailed engravings across a wide range of glass surfaces. This versatility allows for endless creative possibilities, making glass laser engraving machines a valuable tool for artists, designers, businesses, and hobbyists seeking to add personalized and intricate designs to their glass projects with ease and precision.

Efficient and time-saving engraving process

The efficiency and time-saving capabilities of glass laser engraving machines are truly remarkable. By harnessing the power of high-speed lasers, these machines can swiftly and accurately etch intricate designs onto glass surfaces with precision and consistency. This streamlined process not only reduces production time but also ensures that each engraving is completed efficiently without compromising on quality. Whether for mass production or individual customization, the efficiency of glass laser engraving machines makes them a valuable asset for businesses and creators seeking to optimize their workflow and meet tight deadlines with ease.

Non-contact technology minimizes risk of damage to glass surfaces

The non-contact technology employed by glass laser engraving machines is a game-changer in preserving the integrity of glass surfaces. By eliminating physical contact during the engraving process, the risk of damage such as scratches, cracks, or chips is significantly reduced. This gentle approach ensures that delicate or valuable glass items remain unharmed, allowing for flawless and pristine engravings to be achieved with precision and care.

Professional-looking results with sharp clarity

Glass laser engraving machines offer a distinct advantage in delivering professional-looking results with sharp clarity. The precision and accuracy of laser technology ensure that every detail is reproduced with impeccable clarity, creating intricate designs that stand out with exceptional quality. Whether it’s intricate patterns, detailed text, or elaborate graphics, the sharpness of the engravings produced by these machines adds a level of sophistication and elegance to any glass surface. This pro makes glass laser engraving machines a top choice for businesses, artists, and individuals seeking high-quality and visually stunning engraving outcomes.

High initial cost of purchasing a glass laser engraving machine.

The high initial cost of purchasing a glass laser engraving machine can be a significant barrier for individuals and businesses looking to invest in this technology. The upfront expense of acquiring a quality laser engraving machine may pose a financial challenge, especially for small businesses or hobbyists operating on limited budgets. This cost consideration can make it difficult for some potential users to justify the investment, despite the long-term benefits and capabilities that a glass laser engraving machine can offer.

Maintenance and repair costs can be expensive over time.

One notable drawback of glass laser engraving machines is the potential for high maintenance and repair costs over time. As these machines are complex systems that rely on intricate components and precise calibration, regular maintenance is essential to ensure optimal performance. Additionally, in the event of a breakdown or malfunction, repairing or replacing parts can be costly, especially if specialized expertise or proprietary components are required. These ongoing expenses can add up over time and may pose a financial challenge for users seeking to keep their glass laser engraving machine in top working condition.

Limited depth of engraving compared to other methods like sandblasting.

One drawback of glass laser engraving machines is their limited depth of engraving when compared to other methods such as sandblasting. While laser technology excels in creating intricate and precise designs on glass surfaces, the depth of the engraving achieved may be shallower than what can be achieved through sandblasting. This limitation can impact the overall visibility and tactile feel of the engraved design, particularly for applications where a deeper engraving is desired for enhanced texture or durability.

Certain types of glass may not be suitable for laser engraving, limiting material options.

Certain types of glass may not be suitable for laser engraving, which can be a significant limitation when considering material options for projects. Glass compositions that contain impurities or additives, such as leaded glass or tempered glass, may not react well to the intense heat generated by laser engraving machines. This restriction can restrict the range of glass materials that can be effectively engraved, potentially complicating the selection process for users seeking specific characteristics in their engraved pieces. It is essential for individuals working with glass laser engraving machines to carefully consider the compatibility of their chosen glass materials to achieve optimal results without compromising quality or safety.

No Responses