The Power of Engraver Machines: Precision at Your Fingertips

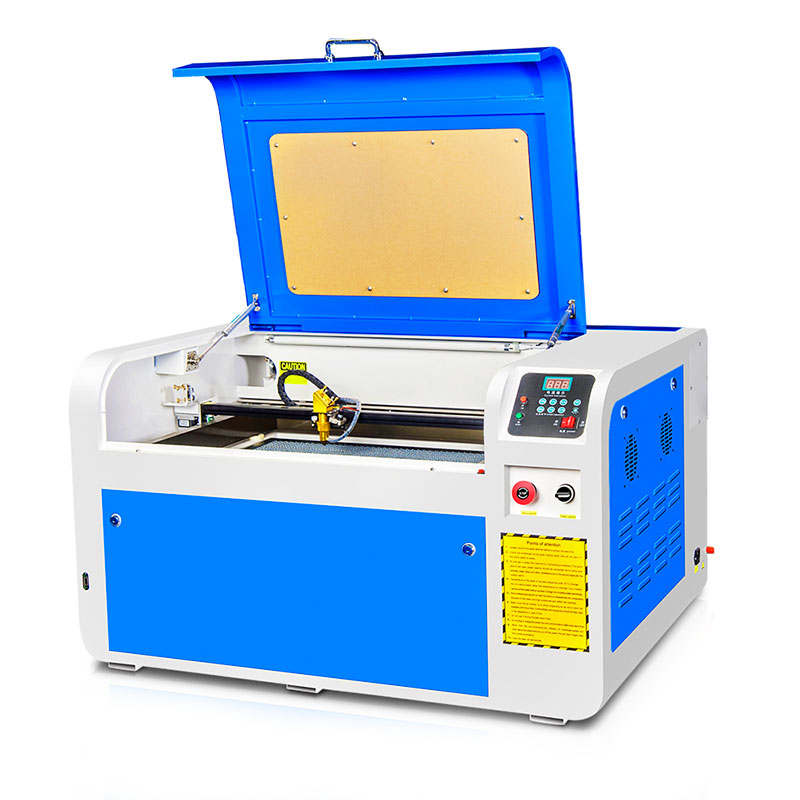

Engraver machines have revolutionized the world of customization and personalization. These powerful tools offer unparalleled precision and control, allowing users to create intricate designs on a variety of materials with ease.

Whether you’re a hobbyist looking to add a personal touch to your creations or a professional seeking to enhance your products, an engraver machine is a valuable asset that can take your work to the next level.

One of the key advantages of engraver machines is their versatility. They can be used on materials such as wood, metal, glass, plastic, and even leather, opening up a world of creative possibilities. From personalized gifts and decorations to industrial marking and branding, the applications of engraver machines are virtually limitless.

What sets engraver machines apart is their precision. With advanced laser technology or mechanical engraving heads, these machines can etch designs with incredible detail and accuracy. This level of precision ensures that every project is executed flawlessly, resulting in professional-looking results every time.

Engraver machines are also known for their efficiency. Whether you’re working on a single piece or mass production, these machines can complete tasks quickly and consistently. This not only saves time but also allows for greater productivity and cost-effectiveness in the long run.

Furthermore, engraver machines are user-friendly and easy to operate. With intuitive software interfaces and customizable settings, users can create designs with ease and experiment with different techniques to achieve their desired outcomes.

In conclusion, engraver machines are powerful tools that offer precision, versatility, efficiency, and ease of use. Whether you’re a beginner or an experienced professional, investing in an engraver machine can elevate your projects and unleash your creativity in ways you never thought possible.

Everything You Need to Know About Engraver Machines: FAQs on Materials, Precision, and More

- What materials can be engraved using an engraver machine?

- What is the difference between laser engraving and mechanical engraving?

- How precise are engraver machines in creating detailed designs?

- Are engraver machines suitable for both personal and industrial use?

- What software is typically used to operate an engraver machine?

- Can engraver machines be used for cutting materials as well as engraving them?

- What safety precautions should be taken when operating an engraver machine?

- How do I maintain and clean an engraver machine to ensure optimal performance?

- Are there different types of engraver machines available, and how do I choose the right one for my needs?

What materials can be engraved using an engraver machine?

Engraver machines are incredibly versatile tools that can engrave a wide range of materials, including wood, metal, glass, plastic, acrylic, leather, stone, and even ceramic. This flexibility allows users to create intricate designs and personalized markings on various surfaces with precision and detail. Whether you’re looking to add a custom touch to your woodworking projects, personalize metal items with intricate patterns, or etch intricate designs on glassware, an engraver machine offers endless possibilities for creative expression across different materials.

What is the difference between laser engraving and mechanical engraving?

When comparing laser engraving and mechanical engraving, the key difference lies in the technology used to create designs on various materials. Laser engraving utilizes a high-powered laser beam to etch or mark surfaces with precision and speed, resulting in clean and detailed results. On the other hand, mechanical engraving involves physically cutting into the material using a rotating tool or bit, offering a tactile feel and deeper engraving depth. While laser engraving is ideal for intricate designs and delicate materials like glass or acrylic, mechanical engraving is preferred for tougher materials such as metal or stone. Each method has its unique strengths and applications, providing users with options to choose based on their specific needs and desired outcomes.

How precise are engraver machines in creating detailed designs?

Engraver machines are renowned for their exceptional precision when it comes to creating detailed designs. Whether using advanced laser technology or precise mechanical engraving heads, these machines can achieve intricate and complex designs with unparalleled accuracy. The ability to etch fine lines, intricate patterns, and small details makes engraver machines a preferred choice for those seeking high-quality results in their projects. With the capability to reproduce designs with meticulous precision, engraver machines excel in bringing even the most intricate visions to life with stunning clarity and sharpness.

Are engraver machines suitable for both personal and industrial use?

Engraver machines are highly versatile tools that cater to both personal and industrial needs with equal efficiency. Whether you’re looking to add a personal touch to your crafts or seeking precise markings for industrial applications, engraver machines are suitable for a wide range of purposes. Their ability to work on various materials and deliver detailed designs makes them ideal for creating personalized gifts, decorations, and prototypes in personal settings. At the same time, their speed, precision, and consistency make them invaluable for industrial tasks such as branding, marking, and part identification. With the flexibility to handle both small-scale projects and large-scale production runs, engraver machines truly bridge the gap between personal creativity and industrial functionality.

What software is typically used to operate an engraver machine?

When it comes to operating an engraver machine, the software plays a crucial role in controlling the machine and creating designs. Typically, engraver machines are compatible with specialized software programs that allow users to import, design, and customize their projects. Popular software options for operating engraver machines include industry-standard programs like CorelDRAW, Adobe Illustrator, AutoCAD, and RDWorks. These software tools provide users with a range of features such as vector drawing capabilities, text manipulation, image tracing, and laser parameter settings. By using the right software in conjunction with an engraver machine, users can unleash their creativity and achieve precise results in their engraving projects.

Can engraver machines be used for cutting materials as well as engraving them?

Engraver machines are primarily designed for engraving materials by etching designs onto their surfaces with precision and detail. While some engraver machines may have cutting capabilities, it’s important to note that their primary function is engraving. Cutting materials typically requires a different type of machine, such as a laser cutter or CNC router, which are specifically designed for cutting through various materials with accuracy and efficiency. If cutting is a primary requirement for your projects, it’s recommended to invest in a machine specifically designed for that purpose to ensure optimal results.

What safety precautions should be taken when operating an engraver machine?

When operating an engraver machine, it is crucial to prioritize safety to prevent accidents and ensure a secure working environment. Some essential safety precautions to follow include wearing appropriate personal protective equipment such as safety goggles and gloves to protect against potential hazards. Additionally, ensure that the work area is well-ventilated to minimize exposure to fumes or particles produced during the engraving process. Always familiarize yourself with the machine’s operating instructions and safety guidelines before use, and never leave the machine unattended while it is in operation. Regular maintenance checks should also be conducted to ensure that the machine is functioning properly and any issues are addressed promptly. By adhering to these safety precautions, operators can minimize risks and operate the engraver machine safely and effectively.

How do I maintain and clean an engraver machine to ensure optimal performance?

Maintaining and cleaning your engraver machine is crucial to ensure its optimal performance and longevity. Regular maintenance includes keeping the machine free of dust and debris, checking and tightening any loose components, lubricating moving parts as needed, and calibrating the machine regularly to maintain accuracy. Cleaning should be done with care using appropriate tools and materials to prevent damage to sensitive components. By following a consistent maintenance schedule and proper cleaning procedures, you can prolong the life of your engraver machine and ensure that it continues to deliver high-quality results for years to come.

Are there different types of engraver machines available, and how do I choose the right one for my needs?

When it comes to engraver machines, there are indeed different types available to cater to various needs and preferences. The key factors to consider when choosing the right engraver machine for your specific requirements include the type of materials you plan to work with, the level of precision and detail you need in your designs, the intended frequency of use, and your budget constraints. Laser engravers are ideal for intricate designs on a wide range of materials, while rotary engravers are better suited for cylindrical objects. By assessing these factors and understanding your priorities, you can select an engraver machine that aligns perfectly with your needs and helps you achieve optimal results in your projects.

No Responses