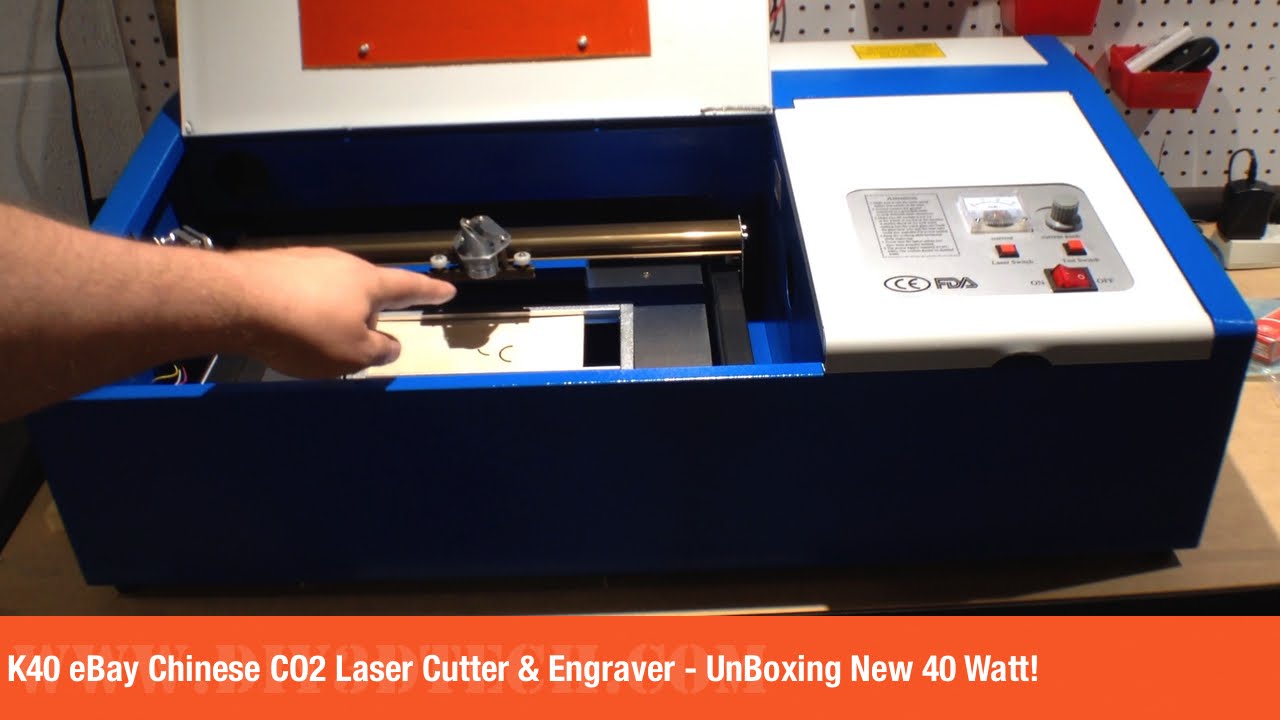

The Power of a 40-Watt Laser Cutter

When it comes to precision cutting and engraving, a 40-watt laser cutter stands out as a versatile and powerful tool. With its ability to cut through various materials with speed and accuracy, this machine has become a favorite among hobbyists, artists, and small businesses alike.

One of the key advantages of a 40-watt laser cutter is its versatility. Whether you’re working with wood, acrylic, leather, or even certain metals, this machine can handle a wide range of materials with ease. Its high-powered laser beam can make intricate cuts and detailed engravings, allowing for endless creative possibilities.

Speed is another factor that sets the 40-watt laser cutter apart. With its fast cutting capabilities, this machine can significantly reduce production time compared to traditional cutting methods. This makes it an ideal choice for those looking to streamline their workflow and increase efficiency.

Furthermore, the precision of a 40-watt laser cutter ensures consistent results every time. Whether you’re creating prototypes, personalized gifts, or intricate designs, this machine delivers crisp edges and fine details with remarkable accuracy.

Overall, the power and precision of a 40-watt laser cutter make it a valuable tool for anyone looking to take their creativity to the next level. With its versatility, speed, and accuracy, this machine opens up a world of possibilities for makers and creators across various industries.

5 Essential Safety and Maintenance Tips for Operating a 40 Watt Laser Cutter

- Ensure proper ventilation to remove smoke and fumes generated during cutting.

- Always wear appropriate safety gear, such as goggles and gloves, when operating the laser cutter.

- Regularly check and align the laser beam to maintain cutting precision.

- Use materials that are approved for laser cutting to prevent damage to the machine or harmful emissions.

- Follow manufacturer’s guidelines for maintenance and cleaning of the laser cutter to prolong its lifespan.

Ensure proper ventilation to remove smoke and fumes generated during cutting.

Ensuring proper ventilation is crucial when using a 40-watt laser cutter to remove smoke and fumes generated during cutting. Adequate ventilation not only helps maintain a clean working environment but also protects your health by preventing the inhalation of potentially harmful particles. By setting up a ventilation system that efficiently removes smoke and fumes, you can enhance the safety and comfort of your workspace while maximizing the performance of your laser cutter.

Always wear appropriate safety gear, such as goggles and gloves, when operating the laser cutter.

When using a 40-watt laser cutter, it is crucial to prioritize safety by wearing proper protective gear, including goggles and gloves. These safety precautions are essential to safeguarding your eyes and hands from potential hazards such as laser beams and heat generated during the cutting process. By consistently wearing appropriate safety gear, operators can minimize the risk of accidents and ensure a safe working environment while operating a powerful tool like a 40-watt laser cutter.

Regularly check and align the laser beam to maintain cutting precision.

Regularly checking and aligning the laser beam on a 40-watt laser cutter is crucial for maintaining cutting precision. Proper alignment ensures that the laser beam remains focused and accurately follows the desired cutting path, resulting in clean cuts and precise engravings. By incorporating this tip into your maintenance routine, you can optimize the performance of your laser cutter and ensure consistent quality output for all your projects.

Use materials that are approved for laser cutting to prevent damage to the machine or harmful emissions.

It is crucial to use materials that are approved for laser cutting when operating a 40-watt laser cutter. Using non-approved materials can not only damage the machine but also create harmful emissions that pose health risks. By following guidelines and using recommended materials, you can ensure the safety of both the machine and yourself, while achieving optimal results in your cutting and engraving projects.

Follow manufacturer’s guidelines for maintenance and cleaning of the laser cutter to prolong its lifespan.

Following the manufacturer’s guidelines for maintenance and cleaning of your 40-watt laser cutter is crucial in prolonging its lifespan and ensuring optimal performance. Regular maintenance tasks such as cleaning the lens, checking for loose parts, and lubricating moving components can help prevent wear and tear, reducing the risk of breakdowns and costly repairs. By adhering to the recommended maintenance schedule, you can keep your laser cutter in top condition, maximizing its longevity and preserving its cutting precision for years to come.

No Responses