The Art of Precision: Laser Engraving Machines for Jewelry

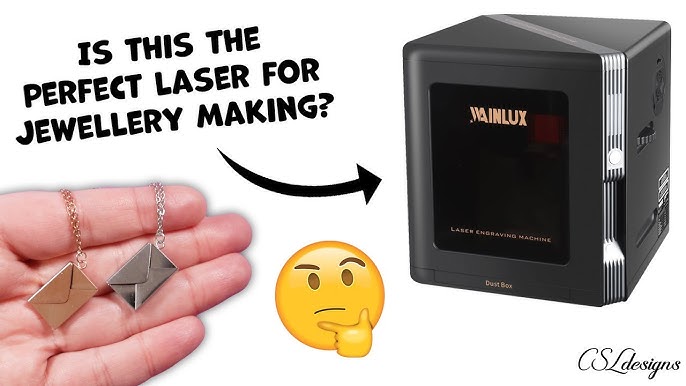

When it comes to creating exquisite and personalized jewelry pieces, precision is key. Traditional engraving methods often fall short when it comes to intricate designs and delicate materials. This is where laser engraving machines shine, offering unparalleled accuracy and versatility in the world of jewelry craftsmanship.

Laser engraving machines utilize advanced technology to etch designs onto various types of jewelry materials with exceptional precision. Whether you’re working with gold, silver, platinum, or even delicate gemstones, a laser engraving machine can bring your creative vision to life with stunning detail and clarity.

One of the key advantages of using a laser engraving machine for jewelry is its ability to create intricate patterns and designs that would be nearly impossible to achieve by hand. From intricate filigree patterns to personalized inscriptions, the precision of a laser ensures that every detail is captured flawlessly.

Furthermore, laser engraving machines offer unmatched speed and efficiency compared to traditional methods. With the ability to automate the engraving process, jewelers can produce high-quality pieces in a fraction of the time it would take using manual techniques.

Another benefit of laser engraving machines is their non-contact process, which minimizes the risk of damage to delicate jewelry pieces. Unlike traditional methods that involve physical contact with the material being engraved, lasers work by focusing a concentrated beam of light onto the surface, resulting in clean and precise engravings without any risk of distortion or damage.

Whether you’re looking to add a personal touch to a piece of fine jewelry or create custom designs for your collection, investing in a laser engraving machine can take your craftsmanship to new heights. With their unmatched precision, speed, and versatility, these cutting-edge tools are revolutionizing the art of jewelry engraving.

Top 5 Advantages of Using Laser Engraving Machines for Jewelry Crafting

- Unparalleled precision for intricate designs on delicate jewelry materials.

- Ability to create custom and personalized engravings with stunning detail.

- Fast and efficient production of high-quality jewelry pieces.

- Non-contact process minimizes the risk of damage to delicate materials.

- Versatile tool that can work with a variety of jewelry materials, including metals and gemstones.

Challenges of Using Laser Engraving Machines for Jewelry Businesses

- High initial cost of purchasing a laser engraving machine can be prohibitive for small jewelry businesses.

- Maintenance and repair costs for laser engraving machines can be expensive over time.

- Learning to operate a laser engraving machine effectively requires training and expertise, which may involve additional investment.

- Laser engraving machines are limited in the size of jewelry pieces they can accommodate, restricting the range of items that can be engraved.

- Certain materials, such as some types of plastics or reflective surfaces, may not be suitable for laser engraving, limiting the versatility of the machine.

- The process of setting up and calibrating a laser engraving machine for optimal results can be time-consuming and complex.

Unparalleled precision for intricate designs on delicate jewelry materials.

The unparalleled precision of laser engraving machines is a game-changer for creating intricate designs on delicate jewelry materials. Traditional methods often struggle to capture the fine details and intricacies of designs on materials like gold, silver, and gemstones. With laser technology, jewelers can achieve a level of precision that is unmatched, ensuring that even the most intricate patterns and designs are etched onto jewelry pieces with exceptional clarity and accuracy. This level of precision not only enhances the aesthetic appeal of the jewelry but also showcases the craftsmanship and attention to detail that sets each piece apart as a true work of art.

Ability to create custom and personalized engravings with stunning detail.

The ability of laser engraving machines to create custom and personalized engravings with stunning detail is a game-changer in the world of jewelry craftsmanship. With unmatched precision and accuracy, these machines can bring intricate designs to life on various materials, from precious metals to gemstones. Whether it’s a personalized inscription, a unique pattern, or a delicate monogram, the level of detail that laser engraving machines can achieve is truly remarkable. This capability allows jewelers to offer their customers one-of-a-kind pieces that are not only visually striking but also deeply meaningful and personalized.

Fast and efficient production of high-quality jewelry pieces.

Laser engraving machines offer the remarkable advantage of fast and efficient production of high-quality jewelry pieces. By automating the engraving process and utilizing advanced technology, these machines can create intricate designs with precision and speed, significantly reducing production time while maintaining exceptional quality standards. Jewelers can now produce customized jewelry pieces efficiently without compromising on craftsmanship, making laser engraving machines a valuable asset in the world of jewelry manufacturing.

Non-contact process minimizes the risk of damage to delicate materials.

One of the standout advantages of using a laser engraving machine for jewelry is its non-contact process, which significantly reduces the risk of damage to delicate materials. Unlike traditional engraving methods that involve physical contact with the surface, lasers operate by focusing a concentrated beam of light onto the material, ensuring precise and clean engravings without compromising the integrity of intricate designs or fragile gemstones. This non-invasive approach not only enhances the overall quality of the finished piece but also provides peace of mind to jewelers working with precious and delicate materials.

Versatile tool that can work with a variety of jewelry materials, including metals and gemstones.

A significant advantage of laser engraving machines for jewelry is their versatility in working with a wide range of materials, from precious metals like gold and silver to delicate gemstones. Unlike traditional engraving methods that may be limited by the type of material, laser technology offers the flexibility to create intricate designs on diverse surfaces with precision and ease. This capability to work seamlessly across different jewelry materials makes laser engraving machines an invaluable tool for jewelers seeking to explore creative possibilities and push the boundaries of traditional craftsmanship.

High initial cost of purchasing a laser engraving machine can be prohibitive for small jewelry businesses.

The high initial cost of purchasing a laser engraving machine can pose a significant challenge for small jewelry businesses looking to invest in this advanced technology. For many artisans and independent jewelers operating on limited budgets, the prohibitive upfront expense of acquiring a laser engraving machine may deter them from harnessing its precision and efficiency benefits. This financial barrier can restrict smaller enterprises from accessing the capabilities of laser engraving machines, potentially limiting their ability to offer personalized and intricately designed jewelry pieces to their customers.

Maintenance and repair costs for laser engraving machines can be expensive over time.

Maintenance and repair costs for laser engraving machines in the jewelry industry can pose a significant challenge over time. The intricate nature of laser technology requires specialized expertise for upkeep and repairs, which can result in higher maintenance expenses compared to traditional engraving methods. Additionally, the sophisticated components and precise calibration of laser engraving machines may necessitate regular servicing to ensure optimal performance, adding to the long-term costs associated with owning and operating these advanced devices. As jewelers weigh the benefits of precision and efficiency offered by laser engraving machines, they must also consider the financial implications of ongoing maintenance and repair expenditures.

Learning to operate a laser engraving machine effectively requires training and expertise, which may involve additional investment.

Mastering the operation of a laser engraving machine for jewelry entails a significant learning curve that demands specialized training and expertise. Acquiring the necessary skills to operate the machine effectively may necessitate additional investment in terms of time and resources. From understanding the intricacies of laser settings to optimizing designs for different materials, honing proficiency in laser engraving is a meticulous process that requires dedication and commitment. However, the long-term benefits of acquiring this expertise can lead to enhanced precision and creativity in jewelry engraving, making the initial investment in training well worth it.

Laser engraving machines are limited in the size of jewelry pieces they can accommodate, restricting the range of items that can be engraved.

One limitation of laser engraving machines for jewelry is their restricted capacity in accommodating larger-sized pieces, which can hinder the engraving of certain items. The size constraints of these machines may limit the range of jewelry pieces that can be engraved, potentially restricting the creativity and customization options available to jewelers and designers. This limitation underscores the importance of considering the dimensions and capabilities of a laser engraving machine when selecting one for jewelry crafting, as it may impact the types of designs and projects that can be executed with precision and efficiency.

Certain materials, such as some types of plastics or reflective surfaces, may not be suitable for laser engraving, limiting the versatility of the machine.

When considering the use of laser engraving machines for jewelry, it is important to note a potential limitation that arises with certain materials. Some types of plastics or reflective surfaces may not be suitable for laser engraving, as the nature of these materials can interfere with the engraving process and result in unsatisfactory outcomes. This limitation can restrict the versatility of the machine, requiring jewelers to carefully select compatible materials to achieve desired results. Despite this con, understanding the capabilities and limitations of laser engraving machines can help artisans make informed decisions when creating intricate and personalized jewelry pieces.

The process of setting up and calibrating a laser engraving machine for optimal results can be time-consuming and complex.

Setting up and calibrating a laser engraving machine for jewelry can present a significant challenge due to the time-consuming and complex nature of the process. Achieving optimal results requires meticulous attention to detail and precision in adjusting various settings to ensure that the laser accurately etches designs onto different types of jewelry materials. From aligning the focal point of the laser beam to fine-tuning power and speed settings, the setup and calibration phase demand patience and expertise to maximize the machine’s performance. Despite this con, mastering the setup process is essential for jewelers aiming to harness the full potential of laser engraving technology in creating stunning and intricate jewelry pieces.

No Responses