The Power of 3D Laser Cutters: Revolutionizing Precision Cutting

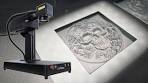

3D laser cutters have emerged as game-changers in the world of precision cutting and engraving. These advanced machines utilize cutting-edge laser technology to create intricate designs with unparalleled accuracy and speed.

One of the key advantages of 3D laser cutters is their ability to work on a wide range of materials, including wood, acrylic, metal, and even glass. This versatility makes them ideal for a variety of industries, from manufacturing and prototyping to arts and crafts.

Unlike traditional cutting methods that rely on physical blades or tools, 3D laser cutters use a focused beam of light to vaporize or melt material with pinpoint precision. This results in clean, smooth cuts that require minimal finishing work, saving both time and resources.

Another significant benefit of 3D laser cutters is their ability to create complex three-dimensional shapes with ease. By adjusting the intensity and focus of the laser beam, operators can achieve detailed cuts and engravings that would be nearly impossible with conventional methods.

Furthermore, 3D laser cutters offer unmatched repeatability and consistency, ensuring that each piece produced is identical to the last. This level of precision is crucial for industries that demand high-quality output on a consistent basis.

As technology continues to advance, we can expect 3D laser cutters to play an increasingly important role in shaping the future of manufacturing and design. Their ability to deliver superior results quickly and efficiently makes them a valuable asset for businesses looking to stay ahead in a competitive market.

In conclusion, 3D laser cutters represent a significant advancement in precision cutting technology. Their versatility, speed, and accuracy make them indispensable tools for a wide range of applications. As they continue to evolve and improve, we can only imagine the endless possibilities they will unlock in the world of design and fabrication.

9 Advantages of 3D Laser Cutters: Precision, Versatility, and Efficiency

- 1. Precision cutting with unparalleled accuracy.

- 2. Versatile, capable of working on various materials like wood, acrylic, metal, and glass.

- 3. Speedy operation for efficient production processes.

- 4. Ability to create intricate designs and complex 3D shapes effortlessly.

- 5. Clean cuts that require minimal finishing work.

- 6. Consistent repeatability for uniform output.

- 7. Reduced material waste compared to traditional cutting methods.

- 8. Minimal risk of damage to the material being cut or engraved.

- 9. Ideal for a wide range of industries from manufacturing to arts and crafts.

5 Drawbacks of 3D Laser Cutters: Cost, Complexity, and Safety Concerns

- High initial cost of acquisition

- Complexity of operation may require specialized training

- Maintenance and servicing can be expensive

- Limited cutting depth compared to other methods

- Potential safety hazards due to the high-powered laser beam

1. Precision cutting with unparalleled accuracy.

One of the most compelling advantages of 3D laser cutters is their ability to achieve precision cutting with unparalleled accuracy. By harnessing the power of focused laser beams, these cutting machines can create intricate designs and shapes with razor-sharp detail and consistency. The pinpoint accuracy of 3D laser cutters not only ensures flawless results but also minimizes material waste, making them an indispensable tool for industries that demand perfection in every cut.

2. Versatile, capable of working on various materials like wood, acrylic, metal, and glass.

One of the standout advantages of 3D laser cutters is their exceptional versatility in working with a diverse range of materials such as wood, acrylic, metal, and glass. This capability allows users to seamlessly transition between different projects and applications without the need for specialized equipment, making 3D laser cutters a cost-effective and efficient solution for industries that require flexibility in material choices. Whether creating intricate designs on wood or precise cuts on metal, the ability of 3D laser cutters to handle various materials with precision opens up a world of creative possibilities for users across different sectors.

3. Speedy operation for efficient production processes.

One of the key advantages of 3D laser cutters is their speedy operation, which enables efficient production processes. Unlike traditional cutting methods that can be time-consuming and labor-intensive, 3D laser cutters work swiftly and accurately, significantly reducing production times. This increased speed not only boosts productivity but also allows businesses to meet tight deadlines and handle high-volume orders with ease. Overall, the rapid operation of 3D laser cutters translates to enhanced efficiency and cost-effectiveness in manufacturing and design processes.

4. Ability to create intricate designs and complex 3D shapes effortlessly.

One of the standout advantages of 3D laser cutters is their remarkable ability to effortlessly create intricate designs and complex 3D shapes with unparalleled precision. By harnessing the focused beam of light, these cutting-edge machines can intricately sculpt materials with incredible detail and accuracy, allowing for the production of stunningly intricate and elaborate designs that would be challenging, if not impossible, to achieve using traditional cutting methods. This capability opens up a world of creative possibilities for industries ranging from manufacturing and prototyping to art and design, empowering users to bring their most ambitious ideas to life with ease.

5. Clean cuts that require minimal finishing work.

One of the standout advantages of using a 3D laser cutter is its ability to produce clean cuts that demand minimal finishing work. The precision and focus of the laser beam result in smooth edges and intricate details, eliminating the need for extensive post-processing. This not only saves time but also enhances efficiency in production processes, allowing for faster turnaround times and higher-quality outputs.

6. Consistent repeatability for uniform output.

One of the key advantages of 3D laser cutters is their consistent repeatability, ensuring uniform output with every piece produced. This precision and reliability are essential for industries that require identical parts or products, as it eliminates variations and errors that can occur with manual cutting methods. The ability of 3D laser cutters to deliver uniform results time after time not only enhances efficiency but also guarantees a high level of quality control, making them invaluable tools for businesses seeking reliable and consistent output.

7. Reduced material waste compared to traditional cutting methods.

One of the significant advantages of 3D laser cutters is their ability to reduce material waste compared to traditional cutting methods. The precision of the laser beam allows for intricate cuts that minimize excess material, resulting in more efficient use of resources. This not only helps businesses save on material costs but also contributes to a more sustainable manufacturing process by reducing overall waste production.

8. Minimal risk of damage to the material being cut or engraved.

One of the standout advantages of using a 3D laser cutter is the minimal risk of damage to the material being cut or engraved. Unlike traditional cutting methods that may cause distortion, chipping, or warping, 3D laser cutters offer a precise and controlled process that ensures the integrity of the material remains intact. This feature not only saves time and resources by reducing the need for rework but also guarantees a high-quality end result with minimal waste, making 3D laser cutters a reliable choice for intricate and delicate projects.

9. Ideal for a wide range of industries from manufacturing to arts and crafts.

The versatility of 3D laser cutters makes them ideal for a wide range of industries, spanning from traditional manufacturing to creative arts and crafts. In manufacturing, these cutting-edge machines offer precision cutting and engraving capabilities that streamline production processes and ensure consistent quality. On the other hand, in arts and crafts, 3D laser cutters empower artists and designers to bring their intricate designs to life with unmatched accuracy and detail. The ability of 3D laser cutters to cater to such diverse industries highlights their adaptability and transformative potential across various fields.

High initial cost of acquisition

One significant drawback of 3D laser cutters is the high initial cost of acquisition. The advanced technology and precision engineering involved in these machines make them a substantial investment for businesses and individuals. The upfront expense of purchasing a 3D laser cutter can be a barrier for smaller operations or those on a limited budget. Additionally, the cost of maintenance, training, and software updates further adds to the overall financial commitment required to effectively utilize and sustain a 3D laser cutter system. Despite their undeniable benefits, the high initial cost of acquisition may deter some potential users from harnessing the full potential of this innovative technology.

Complexity of operation may require specialized training

The complexity of operation associated with 3D laser cutters may pose a significant challenge as it often requires specialized training for operators. Due to the advanced technology and intricate settings involved in controlling the laser beam, users must undergo specific training to ensure safe and effective operation of the machine. This specialized training adds an additional layer of complexity and cost to integrating 3D laser cutters into a workflow, potentially limiting accessibility to those without the necessary expertise or resources.

Maintenance and servicing can be expensive

One notable con of 3D laser cutters is that maintenance and servicing can be expensive. These sophisticated machines require regular upkeep to ensure optimal performance, which can involve costly repairs and replacement of components over time. Additionally, specialized training may be needed to properly maintain and service 3D laser cutters, adding to the overall cost of ownership. For businesses operating on a tight budget, the financial burden of maintaining a 3D laser cutter can be a significant drawback to consider when investing in this technology.

Limited cutting depth compared to other methods

One notable drawback of 3D laser cutters is their limited cutting depth compared to other cutting methods. While these machines excel at precision cutting and intricate designs, their ability to cut through thick materials is often restricted. This limitation can pose challenges when working with materials that require deep cuts or when thicker layers need to be processed. In such cases, alternative cutting techniques may be more suitable to achieve the desired results efficiently.

Potential safety hazards due to the high-powered laser beam

One significant con of 3D laser cutters is the potential safety hazards associated with the high-powered laser beam they emit. The intense concentration of light can pose a risk of eye damage if proper safety precautions are not followed, such as wearing protective eyewear. Additionally, there is a fire hazard when working with certain materials that are highly flammable or prone to overheating. Operators must be well-trained in handling the equipment to minimize the risk of accidents and ensure a safe working environment. Regular maintenance and adherence to safety protocols are essential to mitigate the dangers posed by the powerful laser beam used in 3D laser cutters.

No Responses