The Power of Mini Laser Cutters: Precision in a Compact Package

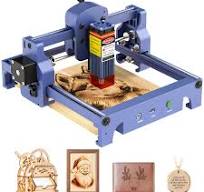

In recent years, mini laser cutters have revolutionized the world of crafting, prototyping, and small-scale manufacturing. These compact yet powerful machines offer unparalleled precision and versatility, making them indispensable tools for hobbyists, designers, and entrepreneurs alike.

One of the key advantages of mini laser cutters is their size. Unlike traditional industrial laser cutters that take up significant space, mini laser cutters are designed to be portable and space-efficient. This makes them ideal for home workshops, small businesses, and educational settings where space is limited.

Despite their small size, mini laser cutters pack a punch when it comes to performance. With high-powered lasers capable of cutting through various materials such as wood, acrylic, leather, and paper with incredible accuracy, these machines enable users to bring their creative ideas to life with ease.

Mini laser cutters are also known for their user-friendly interfaces and intuitive software. Whether you’re a beginner or an experienced user, operating a mini laser cutter is straightforward and hassle-free. Most models come equipped with features such as auto-focus capabilities, adjustable laser power settings, and pre-programmed templates that streamline the cutting process.

From creating intricate designs for jewelry and personalized gifts to prototyping new product concepts and signage for small businesses, the possibilities with mini laser cutters are endless. Their ability to produce clean edges, intricate details, and consistent results make them an essential tool for anyone looking to elevate their projects to the next level.

As technology continues to advance, mini laser cutters are becoming more affordable and accessible than ever before. Whether you’re a hobbyist looking to expand your creative pursuits or a small business owner seeking efficient production solutions, investing in a mini laser cutter can open up a world of possibilities.

Experience the precision and power of mini laser cutters today and unlock your full creative potential in a compact package!

Everything You Need to Know About Mini Laser Cutters: FAQs on Materials, Power, Setup, and More

- 1. What materials can be cut with a mini laser cutter?

- 2. How powerful is the laser in a mini laser cutter?

- 3. What is the cutting area size of a typical mini laser cutter?

- 4. Is it easy to set up and operate a mini laser cutter?

- 5. Can a mini laser cutter engrave as well as cut?

- 6. What safety precautions should be taken when using a mini laser cutter?

- 7. Are there any maintenance requirements for a mini laser cutter?

1. What materials can be cut with a mini laser cutter?

A mini laser cutter is a versatile tool capable of cutting a wide range of materials with precision and accuracy. Common materials that can be cut with a mini laser cutter include wood, acrylic, leather, paper, fabric, cardboard, and certain types of plastics. These machines are ideal for creating intricate designs, personalized items, prototypes, signage, and more. The ability to work with diverse materials makes mini laser cutters a valuable asset for hobbyists, designers, small businesses, and educational institutions seeking to explore the creative possibilities of laser cutting technology.

2. How powerful is the laser in a mini laser cutter?

The power of the laser in a mini laser cutter can vary depending on the specific model and manufacturer. Typically, mini laser cutters are equipped with lasers ranging from 1 watt to 40 watts, with some high-end models reaching even higher power levels. The power of the laser determines its cutting and engraving capabilities, affecting factors such as cutting speed, material thickness, and precision. Higher-powered lasers are capable of cutting through thicker materials more quickly and with greater ease, while lower-powered lasers excel at detailed engraving work on softer materials. It’s essential to consider the intended use of the mini laser cutter when evaluating the power of the laser to ensure it meets your specific cutting and engraving needs effectively.

3. What is the cutting area size of a typical mini laser cutter?

The cutting area size of a typical mini laser cutter can vary depending on the model and manufacturer. Generally, mini laser cutters have a compact cutting area ranging from around 12 inches by 8 inches to 20 inches by 12 inches. It’s essential to consider the dimensions of the cutting area when choosing a mini laser cutter to ensure that it meets your specific project requirements. While smaller cutting areas are suitable for intricate designs and smaller projects, larger cutting areas provide more flexibility for working with larger materials and designs.

4. Is it easy to set up and operate a mini laser cutter?

Setting up and operating a mini laser cutter is generally straightforward and user-friendly. Most mini laser cutters come with detailed instructions and intuitive software that guide users through the setup process step by step. Additionally, many models feature plug-and-play functionality, making it easy to get started right out of the box. Operating a mini laser cutter typically involves loading your design file, adjusting settings such as laser power and speed, and initiating the cutting or engraving process with just a few clicks. With user-friendly interfaces and automation features, setting up and operating a mini laser cutter is a seamless experience for both beginners and experienced users alike.

5. Can a mini laser cutter engrave as well as cut?

Yes, a mini laser cutter can both engrave and cut with precision. Mini laser cutters are equipped with high-powered lasers that are capable of performing both engraving and cutting tasks on a variety of materials such as wood, acrylic, leather, and paper. The versatility of mini laser cutters allows users to create intricate designs through engraving or achieve precise cuts with ease. Whether you’re looking to add personalized details to your projects or create custom shapes and patterns, a mini laser cutter provides the capabilities to handle both engraving and cutting tasks effectively.

6. What safety precautions should be taken when using a mini laser cutter?

When using a mini laser cutter, it is essential to prioritize safety precautions to ensure a secure working environment. Some key safety measures to consider include wearing appropriate protective gear, such as safety goggles to shield your eyes from laser beams. Additionally, always operate the mini laser cutter in a well-ventilated area to minimize exposure to fumes and ensure proper airflow. It is crucial to follow manufacturer guidelines for safe operation, including keeping the machine clean and well-maintained. Never leave the mini laser cutter unattended while it is in operation and always have fire extinguishing equipment nearby as a precaution. By following these safety precautions diligently, you can enjoy the benefits of using a mini laser cutter while minimizing risks and ensuring a safe workspace.

7. Are there any maintenance requirements for a mini laser cutter?

Maintenance requirements for a mini laser cutter are essential to ensure optimal performance and longevity of the machine. Regular maintenance tasks may include cleaning the lens to remove any debris or residue that can affect cutting precision, checking and adjusting the laser alignment for accurate cuts, inspecting and replacing worn-out parts such as belts or mirrors, and ensuring proper ventilation to prevent overheating. By following a routine maintenance schedule, users can keep their mini laser cutter in top condition and avoid potential issues that may arise from neglecting upkeep tasks.

No Responses